Transforming organic compost waste into uniform, easy-to-use granules increases the value of your product. In the organic fertilizer production chain, the Organic Fertilizer Granulator Machine is the core equipment that transforms organic compost into easy-to-use granules farmers love to use. However, with several options in the market it is hard to choose which Organic Fertilizer Granulator Machine is right for your business. Selecting the right one can be a complex decision. This directly impacts your production efficiency and product quality.

LANE Heavy Industry Company Ltd, a professional agricultural equipment manufacturer, recommends focusing on three mainstream types. Those are disc, rotary drum, and stirring pin granulators. They all have unique advantages tailored to different business needs. In this article we will explain the strengths and ideal applications of each granulation machine to help you make an informed decision.

Disc granulator, also known as pan granulator, consists of a rotating, inclined disc. It is a classic cost-effective solution. This is a favorite of small size businesses or farmers. The fine powder compost is fed into its tilted disc (usually 30-50 degrees). As it rotates the tumbling and cascading causes friction to roll organic powder into spherical granules. Water or other liquid binders are sprayed onto the materials to facilitate this agglomeration.

LANE’s disc granulator stands out with its variable-frequency speed control system, which allows adjusting the disc rotation speed (10-25 rpm) to produce 2-6mm granules of uniform size. This Organic Fertilizer Granulator Machine is coated with wear-resistant polyurethane, reducing material sticking which lowers maintenance cost.

The disc angle and rotation speed can be adjusted in real time with the built-in PLC system, which allows operators to control granule size with precision without stopping production. With the right Organic Fertilizer Granulator Machine, businesses can achieve consistent granule quality and improve overall production efficiency.

Disc Granulator is Ideal for:

Pros:

Cons:

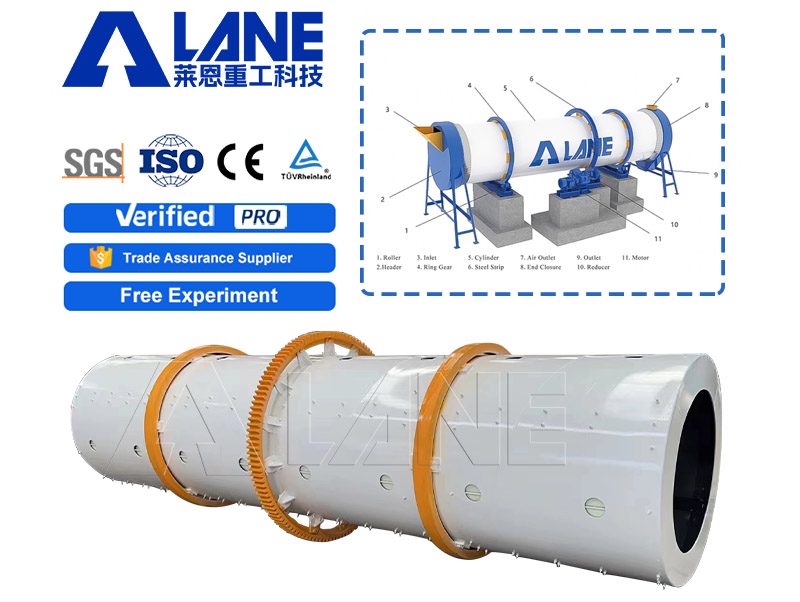

For large scale production lines with high output per hour, the rotary granulator is the go-to machine. This is a large, cylindrical drum which rotates at 11-13 times per minute. It is set at a slight incline. The raw materials are fed into the higher end. Materials inside are continuously turned and extruded to form granules under the combined action of gravity and mechanical force.

It is made for customers focusing on large-scale commercial production. LANE’s rotary drum granulator is equipped with a precision humidification system, ensuring even mixing and preventing uneven granule size. This Organic Fertilizer Granulator Machine can achieve hourly output of 20 tons per hour. Choosing the right Organic Fertilizer Granulator Machine ensures high efficiency and uniform granule quality for large-scale operations.

Rotary drum granulator is ideal for:

Pros:

Cons:

This Organic Fertilizer Granulator Machine is also known as a new type wet granulator. It has high efficiency and strong adaptability. It can easily make granulation of high fiber and sticky materials. It uses a high-speed rotating shaft equipped with “pins” or stirring teeth. The raw materials are fed into the chamber where it uses high-speed rotating stirring pins to knead and extrude materials into granules, realizing “forced granulation” without relying on centrifugal force.

LANE’s stirring pin has adopted a spiral design that enhances material turnover, which in turn reduces the energy consumption by 15%. The granular formation rate of this Organic Fertilizer Granulator Machine is 85-97%. The granulation quality of this machine is excellent.

Stirring pin granulator is ideal for:

Pros:

Cons:

Choosing the right Organic Fertilizer Granulator Machine requires proper considerations. Sometimes it can be decided on the volume of the product, raw material type, budget, and product standards.

LANE industry goes beyond providing single machines. We provide customized solutions for the Organic Fertilizer Granulator Machine. For example, we match disc granulator with a small-scale fermentation system for family farms, combine stirring pin with a continuous drying line for industrial production, or for large scale compound fertilizers production combining rotary drum granulator with a full production solution.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520