Have you ever wondered how farms manage to produce tons of organic fertilizer efficiently every day? This Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output will walk you through it, step by step. With more than 20 years of experience in China’s fertilizer machinery industry, we’ve seen everything from tiny workshops to huge industrial plants, and one thing is clear: the right equipment and smart planning can make a huge difference.

Organic fertilizer is more than just a trend—it’s becoming essential for sustainable farming. And if you want to meet the growing demand, boosting output while keeping quality high is key. That’s exactly what this guide is about.

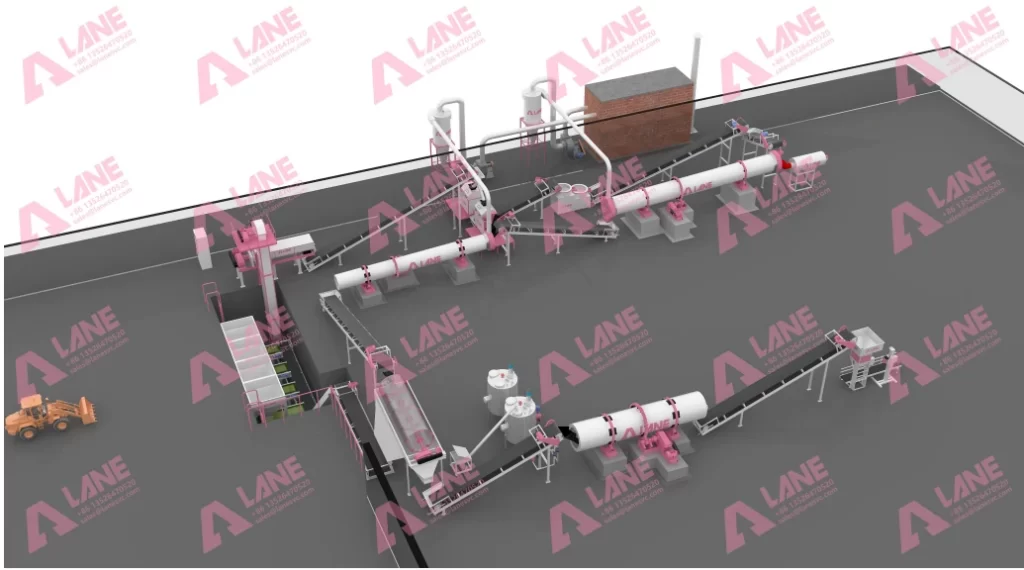

So, what machines do you actually need? Here’s the scoop from our Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output:

Crusher – Vertical Crusher: Think of it as the first gatekeeper. Big chunks of organic material get crushed into fine particles. If this step isn’t done right, the rest of the process suffers.

Mixer – Double Shaft Mixer: Imagine throwing all ingredients in a giant blender—that’s basically what this machine does. It ensures that nutrients are evenly distributed, which is crucial for pellet consistency.

Granulator – Disc Granulator: This is where the magic happens. The blended materials become round, uniform pellets. The Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output emphasizes that granulator efficiency directly impacts your total output.

Dryer – Rotary Drum Dryer: Hot and humid pellets are a no-go. The dryer removes excess moisture and makes pellets durable.

Cooler – Counter Flow Cooler: After drying, pellets are hot and fragile. The cooler ensures they come out strong and ready for handling.

Screening Machine – Rotary Screener: Not all pellets are the same size. This machine separates the oversized and undersized pieces, so every bag is top-quality.

Coating Machine – Fertilizer Coating Equipment: A little extra layer goes a long way—prevents dust, maintains nutrients, and gives your pellets a polished finish.

Packaging Machine – Automatic Bagging System: Finally, automation packs your pellets quickly and hygienically. Less manual labor, more efficiency.

Each piece of equipment is like a player on a soccer team: alone they’re fine, but together they win championships.

Machines are important, but people make the difference. This Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output highlights our professional engineering team. They’ve worked with clients who have unusual raw materials, different production scales, or tight space constraints.

One farm came to us with a mix of high-moisture waste and crop residues. By customizing their line—adding extra drying capacity and adjusting granulator settings—we helped them increase output while keeping pellet quality consistent. Smart engineering means higher efficiency, lower energy bills, and less waste.

Setting up a production line isn’t just about buying machines. Our Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output covers full-service support:

Installation: We handle assembly, calibration, and trial runs so you can start production without headaches.

Maintenance: Machines need TLC. Regular checks prevent unexpected downtime.

Troubleshooting: Quick fixes keep production moving, even when issues pop up.

Upgrades: Technology moves fast—our team ensures your line stays competitive.

With this level of support, clients focus on growing their business, not worrying about technical details.

Quality isn’t negotiable. All machines in this Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output meet ISO9001 and CE certifications. That means reliable performance, safety, and long-term durability.

Certified equipment reduces energy use, keeps operations smooth, and ensures your pellets meet international quality expectations. In short, quality machines save you money and headaches.

Even the best equipment needs care. Here’s some practical advice from the Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output:

Little things like this prevent downtime and maintain high output levels.

Sometimes things go wrong, even in well-run factories. The Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output explains how to fix common issues:

Pellets breaking easily: Moisture adjustment or granulator calibration can help.

Uneven pellet size: Recalibrate the disc granulator or screener.

Low output: Check feed rates and machine synchronization.

Knowing how to troubleshoot keeps production smooth and predictable.

Organic fertilizer demand is rising, and technology is evolving fast. The Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output predicts smarter lines with AI-based monitoring, automated quality checks, and energy-efficient dryers.

Farms that adopt these innovations can produce more pellets, reduce waste, and stay ahead of the competition. Staying informed about trends is almost as important as choosing the right equipment.

Let’s put theory into practice. One mid-sized farm upgraded their line using our Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output, adding a second granulator and automated screening. The result? Output jumped nearly 50%, labor costs dropped, and pellet consistency improved.

Another client implemented a fully automated line with continuous monitoring. Their production became more predictable, energy usage decreased, and their business grew steadily. Stories like these show how the right guidance and equipment can transform a fertilizer business.

To wrap it up, this Organic Fertilizer Pellet Production Line Equipment Guide: Achieving Up to 50% More Output offers everything you need to understand, plan, and run a high-efficiency organic fertilizer production line. From core machinery to expert engineering, maintenance tips, and real-world success stories, it’s your roadmap to higher output, better quality, and long-term success.

Whether you’re starting fresh or upgrading an existing line, following this guide ensures your production line runs smoothly, produces top-quality pellets, and keeps your business ahead in the growing organic fertilizer market.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520