With rising fertilizer prices and increasing environmental pressure, farm waste is no longer viewed as a burden that needs to be disposed of. Instead, it is increasingly recognized as a valuable on-farm resource with real economic and ecological potential. Livestock manure, crop straw, and other organic residues contain abundant nutrients that can significantly improve soil fertility when properly processed. Organic Fertilizer Production Equipment for Small Farms provides an efficient and affordable way to transform these materials into stable, nutrient-rich fertilizer products suitable for continuous agricultural use.

This guide explains how small farms can build a practical waste recycling system by adopting suitable equipment and proven processing methods. Through controlled fermentation and standardized post-treatment, farmers can reduce environmental pollution, lower their dependence on purchased chemical fertilizers, and improve soil health. Ultimately, this approach supports a sustainable agricultural production model that delivers long-term economic returns while promoting responsible resource utilization.

For small-scale operations, investing in Organic Fertilizer Production Equipment for Small Farms is not just a cost-saving decision—it is a strategic move toward self-sufficiency. These systems allow farms to produce nutrient-rich organic fertilizer internally, reducing dependence on purchased chemical fertilizers while improving soil health.

By closing the nutrient loop on-site, small farms can establish a stable organic cycle that improves both productivity and resilience.

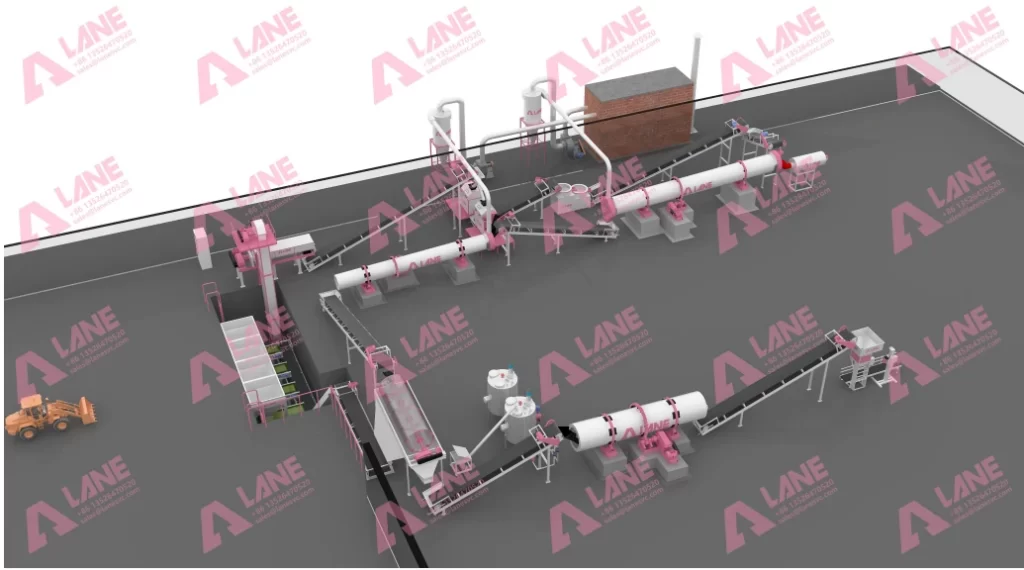

A standard Organic Fertilizer Production Equipment for Small Farms workflow includes:

Raw Material Pretreatment

Crushing, blending, moisture control, and carbon-to-nitrogen ratio adjustment.

Fermentation Stage

Aerobic fermentation at 55–65°C for 15–30 days, eliminating pathogens and weed seeds.

Post-Fermentation Processing

Crushing, granulation, drying, screening, and packaging to produce stable, market-ready fertilizer.

This controlled process ensures clean, eco-friendly production with high nutrient retention.

A complete Organic Fertilizer Production Equipment for Small Farms setup typically includes:

Each machine can be modularly selected based on farm size and budget.

The main benefits of Organic Fertilizer Production Equipment for Small Farms include:

Compared with traditional composting, modern equipment shortens production cycles from 2–3 months to 30–45 days while increasing nutrient uniformity by over 25%.

With an initial investment of approximately 50,000–80,000 RMB, small farms using Organic Fertilizer Production Equipment for Small Farms can process 500–1,000 tons annually, typically achieving ROI within 1.5–2 years.

Studies and field cases show that long-term use increases soil organic matter by an average of 1.5% within three years, significantly boosting crop yield and profitability.

Routine maintenance ensures stable performance of Organic Fertilizer Production Equipment for Small Farms.

Due to limited labor, farms should adopt simplified maintenance strategies:

This approach minimizes downtime and service costs.

Across the globe, small farms are successfully adopting Organic Fertilizer Production Equipment for Small Farms to achieve both economic and ecological benefits. By selecting experienced equipment suppliers, farmers can receive full support—from process design to installation and training—ensuring smooth project implementation.

If you are ready to transform farm waste into profit, Organic Fertilizer Production Equipment for Small Farms is a practical and sustainable starting point.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520