The demand for organic fertilizer is increasing because of the heavy use of chemical fertilizers. Years of using chemical fertilizers have destroyed the microbial life of the soil. By destroying the microbial life, the soil loses its own nutrient-making source. This makes farmers more dependent on chemical fertilizers. Organic fertilizer provides a solution for this. For entrepreneurs and small to medium-sized enterprises, this represents a significant opportunity.

An organic fertilizer production line for a small factory gives small businesses and farmers the ability to practice sustainable farming. It is not only environmentally friendly, it is also a profitable venture. The key to success lies in implementing an efficient, reliable, and appropriately scaled organic fertilizer production line for a small factory.

The global agriculture industry is focusing more on sustainability, and organic farming is the poster child of that movement. Small factories that produce organic fertilizers have the chance to capitalize on this trend. This provides farmers with affordable and eco-friendly alternatives to traditional fertilizers.

Investing in an organic fertilizer production line for a small factory offers several benefits:

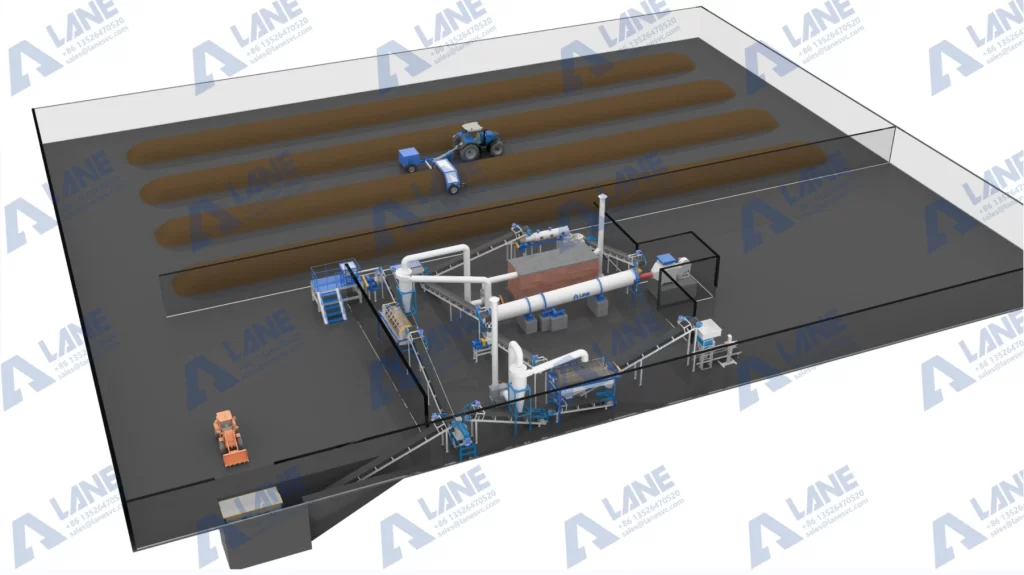

LANE Heavy Industry offers a comprehensive range of machinery that can be used in every stage of organic fertilizer production. Our equipment is specifically designed to enhance efficiency, reduce operational costs, and ensure high-quality output in small-scale production lines.

From composting and crushing to granulating and packaging, our machinery ensures smooth, seamless operations. They create products according to the customer’s needs. This makes it easier for customers to enter a niche market.

To establish an organic fertilizer production line for a small factory, some key components are necessary. Each machine plays an important role in the production process.

Composting Equipment

Composting is the first step in producing organic fertilizer. The raw materials, such as animal manure, agricultural waste, and other organic matter, must undergo a controlled decomposition process to convert them into valuable compost. LANE Heavy Industry’s composting equipment helps small factories to speed up the composting process. LANE compost turners and fermentation tanks are designed to optimize aeration, moisture control, and temperature regulation. They are all essential for high-quality compost.

Crushing and Screening

Once the compost is ready, it needs to be processed into a fine powder. This helps with the even distribution of nutrients. LANE’s crushing and screening machines ensure that compost particles are broken down into smaller, uniform sizes. These machines are efficient, durable, and easy to operate, making them perfect for small factories.

The screening machine also removes any debris and stones from the compost. This ensures that only pure, high-quality organic matter enters the next stage of production.

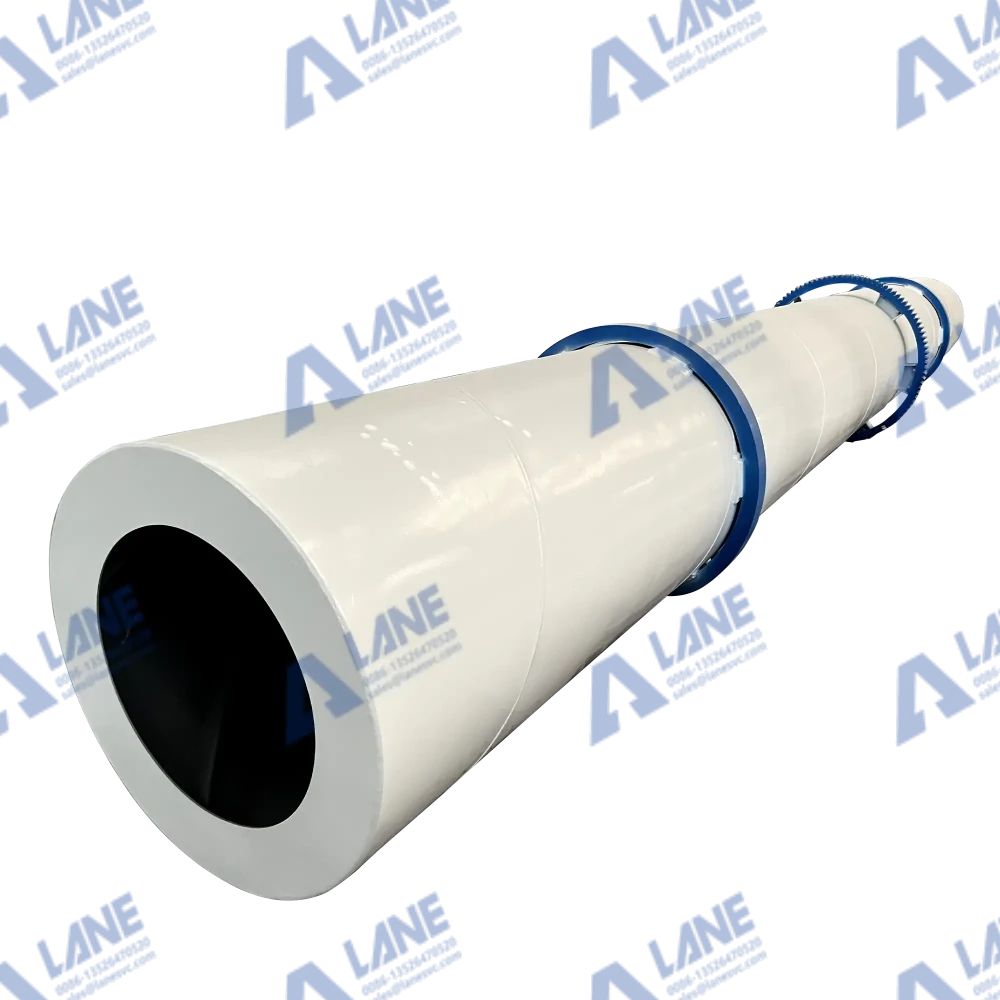

Mixing and Granulating

Granules are easy to spread across the farm and are more highly valuable than powdered compost. The next step of the process is mixing and granulating. The composted materials are mixed with other trace elements, minerals, and natural binders.

LANE Heavy Industry’s mixing and granulating equipment guarantees that the nutrients are evenly distributed. Our double-shaft mixer and stirring pin granulator are designed to improve the consistency of the final product.

After granulating, the organic fertilizer needs to be dried to remove excess moisture and then cooled to prepare it for packaging.

LANE’s drying and cooling machines are designed to work together to maximize efficiency while minimizing energy consumption. These systems ensure that the fertilizer is dried evenly and cooled rapidly.

Packaging and Storage

Once the organic fertilizer has been screened for oversized and undersized granules, the on-size granules are sent to the packaging machine. LANE provides fully automated packaging systems that can handle bulk packaging or small retail packages. This system is designed to work seamlessly with the entire production line.

LANE Heavy Industry machinery is built to meet the needs of small-scale factories.

Building an organic fertilizer production line involves a significant initial investment. It can be highly profitable in the long term. The main costs include the purchase of machinery, raw materials, operational expenses (such as labor and utilities), and marketing.

However, by opting for LANE Heavy Industry’s machinery, small factories can benefit from high-quality equipment at competitive prices. Also, the durability and energy efficiency of the equipment will help lower ongoing operational costs.

Building an organic fertilizer production line for a small factory can be a highly rewarding venture with proper machinery and planning. By investing in LANE’s reliable, cost-effective, and customizable machinery, small factories can ensure smooth operations, higher productivity, and long-term success in the organic fertilizer industry.

How much space is required to set up an organic fertilizer production line?

The space needed depends on the scale of production and the type of machinery. Typically, small factories need around 500 to 1000 square meters to house the entire production line.

Can small factories start with a smaller production line?

Yes, LANE Heavy Industry offers scalable equipment, which means small factories can start with a smaller production line and expand as their business grows.

What types of raw materials are used in organic fertilizer production?

Common raw materials include animal manure, agricultural waste, food scraps, plant residues, and other organic matter.

How long does it take to set up an organic fertilizer production line?

Depending on the complexity of the equipment and factory size, setting up a production line can take anywhere from a few weeks to a couple of months.

Is LANE Heavy Industry’s machinery easy to maintain?

Yes, LANE’s machinery is designed for durability and low-maintenance operation. However, regular cleaning and inspections are recommended to ensure optimal performance.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520