Indonesia is one of the largest agricultural countries in Southeast Asia, producing massive amounts of livestock manure, crop residues, and food waste every year. Managing this organic waste efficiently has become a key issue for both environmental protection and sustainable agriculture.

An increasing number of local farms and agribusinesses are turning to modern organic fertilizer production lines in Indonesia to convert waste into valuable organic fertilizer — improving soil health, reducing pollution, and supporting national food security.

The Growing Demand for Organic Fertilizer in Indonesia

With a population exceeding 270 million and agriculture contributing over 13% of GDP, Indonesia’s demand for organic fertilizer is rapidly rising.

Long-term use of chemical fertilizers has degraded soil structure and reduced organic matter. Organic fertilizers are now recognized as the sustainable alternative that restores soil balance, supports microbial activity, and increases long-term productivity.

Government programs such as “Go Organic 2030” and growing consumer demand for eco-friendly produce have accelerated the development of organic fertilizer production lines across Indonesia, particularly in provinces like East Java, Central Java, and Sumatra.

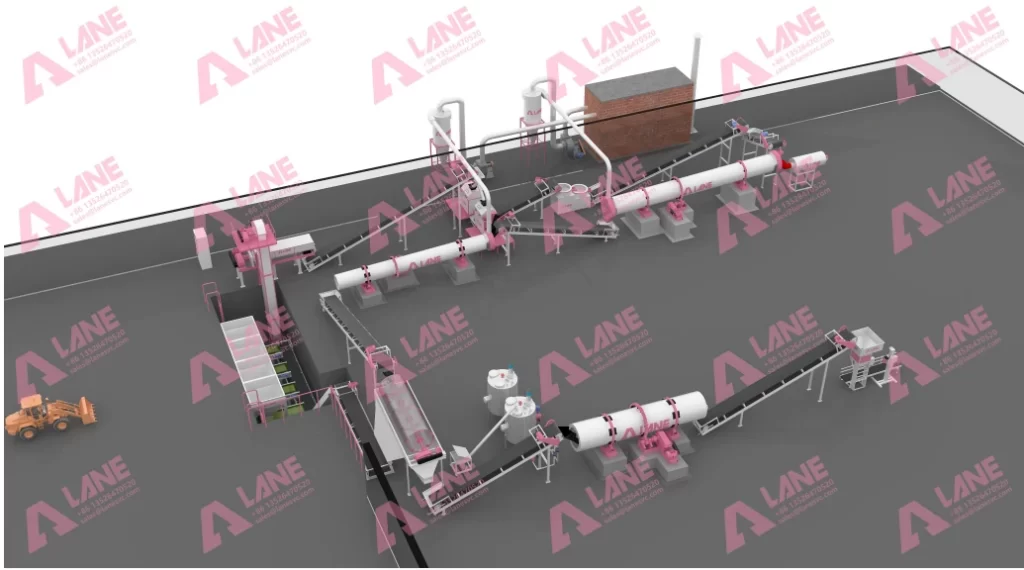

Process Flow of an Organic Fertilizer Production Line in Indonesia

An organic fertilizer production line is designed to transform raw organic waste into stable, high-quality granular fertilizer through several processing stages.

Below is a breakdown of each stage using LANE Heavy Industry’s equipment solutions.

1.Raw Material Mixing

Raw materials such as poultry manure, cow dung, rice husk, palm waste, and composted straw are first mixed using a horizontal mixer or double-shaft mixer.

This step adjusts the carbon-to-nitrogen (C/N) ratio and moisture content, ensuring balanced fermentation and uniformity before composting.

2.Composting and Fermentation

The mixed materials are transferred to a composting area for aerobic fermentation.

Depending on the project scale, LANE provides different compost turners:

Crawler Type Compost Turner – efficient for outdoor windrow composting.

Groove Type Compost Turner – ideal for controlled indoor fermentation.

These machines introduce oxygen and maintain optimal temperature (55–70°C) for about 15–20 days, killing pathogens and accelerating organic matter breakdown.

Once the compost becomes dark and odorless, it is ready for further processing.

3.Crushing — Vertical Shaft Crusher

After fermentation, the composted material often contains clumps or fibrous residue. It is processed using a vertical shaft crusher, which finely crushes materials from top to bottom through high-speed rotating blades.

This ensures uniform particle size, improving granulation efficiency and product quality.

Compared to traditional semi-wet crushers, the vertical shaft crusher has higher output and less clogging, especially suitable for moist materials common in Indonesia’s humid climate.

4.Granulation — Stirring Pin Granulator

The crushed material is then transferred to a stirring pin granulator for shaping.

This machine combines mechanical agitation and rolling force to form dense, round granules without requiring high temperature or pressure.

The stirring pin granulator is particularly effective for organic materials such as poultry manure, cow dung, and composted residues, creating uniform pellets with strong hardness and good nutrient retention.

The result is granules with a diameter of 3–5 mm — suitable for both field application and commercial packaging.

5.Screening — Rotary Drum Screener

After granulation, the product passes through a rotary drum screener to separate qualified pellets from undersized or oversized ones.

Qualified pellets move forward for drying and packaging.

Oversized or under-formed particles are returned to the granulator for reprocessing.

This screening step improves product uniformity and commercial value, ensuring every bag meets Indonesian agricultural standards.

6.Drying and Cooling

The screened fertilizer granules are sent to a rotary drum dryer, where hot air reduces their moisture content to around 10–15%.

They are then cooled by a rotary drum cooler, which prevents clumping and improves storage stability.

Proper drying and cooling are critical in Indonesia’s tropical environment to avoid moisture absorption during storage.

7.Packaging

Finally, the finished organic fertilizer is packed using an automatic weighing and bag-sealing machine.

The system can handle 10–50 kg bags efficiently, preparing the product for market distribution or in-house agricultural use.

Advantages of an Organic Fertilizer Production Line in Indonesia

Environmental Protection – Reduces pollution from livestock and crop waste.

Soil Improvement – Restores organic matter and boosts microbial activity.

Economic Value – Turns farm waste into marketable fertilizer.

Energy Efficiency – Machines such as the stirring pin granulator and vertical crusher require less energy while maintaining high output.

Government Support – Indonesia encourages local organic fertilizer production through cooperative and private sector initiatives.

Case Study: Poultry Manure Fertilizer Project in East Java

In East Java, a poultry farm installed a 3–5 tons per hour organic fertilizer production line designed by LANE Heavy Industry.

The line included:

Horizontal mixer

Crawler type compost turner

Vertical shaft crusher

Stirring pin granulator

Rotary drum screener

Rotary dryer and cooler

Automatic packaging system

After six months of operation, the farm achieved:

Reduction of manure waste by 90%

Organic fertilizer output of 3,000 tons per year

New income from fertilizer sales to local vegetable growers

LANE provided on-site installation and training, helping local operators master daily maintenance and process control.

Why Choose LANE Heavy Industry

LANE Heavy Industry has over 15 years of experience in designing organic fertilizer production lines for diverse markets, including Indonesia, Malaysia, and the Philippines.

We provide complete turnkey solutions from raw material handling to finished packaging.

Key Benefits of LANE Equipment:

Modular design, easy to expand or upgrade

Custom configuration for raw material types and local humidity

Energy-saving design and corrosion-resistant structure

24/7 technical support and spare parts supply

With our expertise, each organic fertilizer production line in Indonesia is optimized for local conditions — high humidity, variable raw materials, and regional regulations.

Conclusion

Building an organic fertilizer production line in Indonesia is a sustainable and profitable investment.

By using efficient machines such as the vertical shaft crusher, stirring pin granulator, and rotary drum screener, farms and enterprises can convert waste into high-value fertilizer while protecting the environment.

As Indonesia moves toward greener agricultural practices, locally operated fertilizer production lines will play a vital role in reducing chemical dependency and improving long-term soil health.

LANE Heavy Industry remains a trusted partner for technology, design, and equipment supply in this growing field.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520