Organic Fertilizer Production Line in South Africa: A Turnkey Solution by LANE Heavy Industry

Introduction: The Green Revolution in South African Agriculture

South Africa is witnessing a surge in demand for organic fertilizer, driven by environmental concerns and agricultural sustainability needs. South Africa has relied on the excessive use of chemical fertilizers to meet the nutrient demand for crops, leading to significant soil acidification and degradation.

Data from the UN Food and Agriculture Organization shows South Africa’s fertilizer application increased from 70.4 kg per hectare in 2018 to 72.8 kg in 2020. Meanwhile, the Ukraine war disrupted global chemical fertilizer supply chains, increasing chemical fertilizer prices.

For agri-businesses, entrepreneurs, and farmers, this presents a significant opportunity to invest in an organic fertilizer production line in South Africa. With the right planning, an organic fertilizer production line in South Africa can deliver sustainable crop yields while boosting profitability. LANE Heavy Industry, with 20 years of experience in the fertilizer industry, can provide a turnkey solution to create a greener, more profitable future.

The Growing Demand for organic fertilizer production line in South Africa

The demand for organic fertilizer keeps growing in South Africa. The government is also focusing on providing incentives to agri-business. The reasons are:

- Soil Health Crisis: Decades of chemical fertilizer use have degraded soils, reduced organic matter, and harmed water retention. Organic fertilizers rebuild soil structure and microbial life.

- Water Conservation: Organic matter improves soil’s water-holding capacity. South Africa is a water-scarce country. Increasing the water capacity of soil will increase food production.

- Market Access & Premiums: Both local and international markets show a strong preference for organically grown produce. Organic food now commands higher prices.

- Waste-to-Wealth Initiative: Agricultural waste (manure, crop residues), municipal green waste, and food processing by-products can be transformed from disposal liabilities into valuable, nutrient-rich fertilizer.

- Policy Support: Governmental and institutional focus on sustainable agriculture means a favorable environment for businesses that want to produce organic fertilizer.

What is a Turnkey organic fertilizer production line in South Africa?

A turnkey organic fertilizer production line in South Africa is a complete, ready-to-operate system supplied by a single provider. It encompasses the entire process from raw material handling to the final packaged product. “Turnkey” literally means the client can “turn the key” and begin operations.

The machinery provider is responsible for design, manufacturing, installation, and training. This approach eliminates the complexity of sourcing equipment from multiple vendors.

LANE Heavy Industry: Your Trusted Turnkey Partner

LANE Heavy Industry has established itself as a leader in the design and supply of efficient fertilizer production solutions. We understand the challenges, from variable raw materials to specific climatic conditions in South Africa. We provide a partnership. Our turnkey service for an organic fertilizer production line in South Africa is built on:

- Localized Expertise: We provide tailored solutions for South African raw material profiles (e.g., chicken litter, cattle manure, vineyard waste, composted green waste).

- End-to-End Responsibility: We provide training to technicians so they can manage the entire project lifecycle.

- Robust Engineering: Our equipment is durable and built to last in demanding agricultural and industrial environments.

- Ongoing Support: We provide spare parts, maintenance guidance, and operational after-sales advice long after installation.

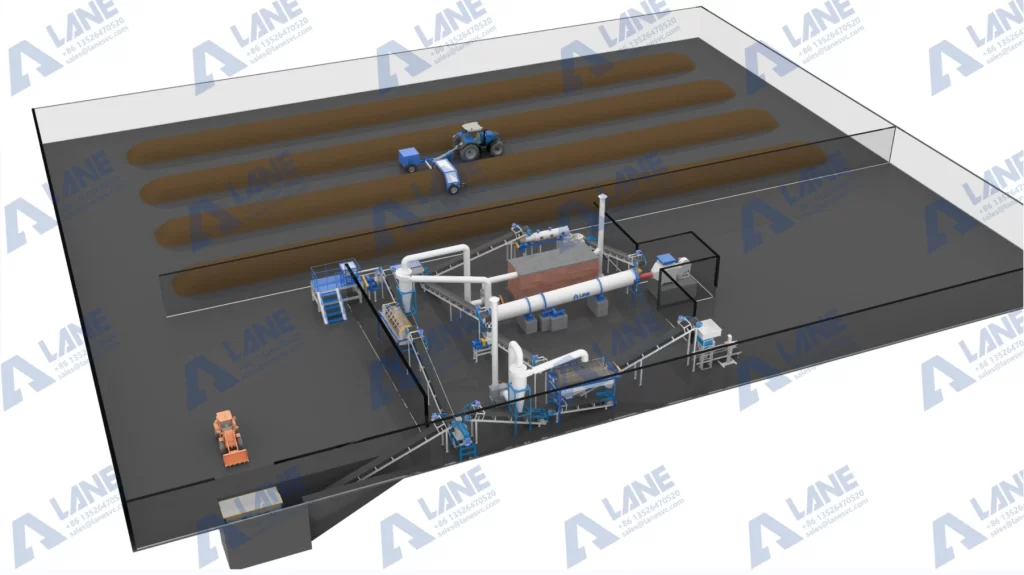

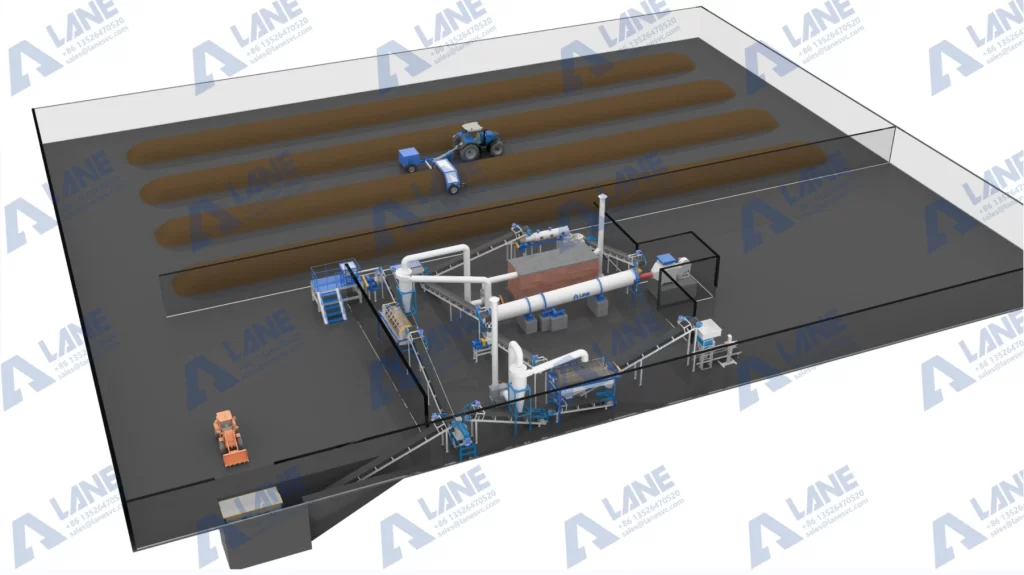

Key Components of a LANE organic fertilizer production line in South Africa

A complete LANE production line integrates key machines to automate and optimize the process:

- Fermentation & Composting Systems: LANE provides compost turners (crawler or groove-type) or fermentation tanks for aerobic fermentation; this is crucial for pathogen elimination and stability.

- Feeding System: Our dynamic feeding system acts as temporary storage and supplies raw material to the production line.

- Crushing & Screening: Our vertical crusher or hammer crusher breaks down clumps and stalks, while screening drums separate fine, saleable powder from coarse materials for re-crushing.

- Mixing & Blending: Our horizontal dual-shaft mixers ensure homogeneous blending of raw materials and additives (like beneficial microbes or mineral supplements).

- Granulation: LANE provides stirring teeth granulators or disc granulators to transform powder into uniform, dust-free granules that are preferred for mechanized farming.

- Drying & Cooling: Rotary dryers reduce moisture content after granulation, followed by coolers to stabilize the granules for storage.

- Coating & Packaging: LANE’s rotary coating drums apply anti-caking agents, and fully automatic weighing & packaging machines bag the final product efficiently.

The Production Process: From Raw Material to Premium Product

A well-designed LANE line streamlines the following process:

- Pre-treatment & Fermentation:Manure or waste is piled into windrows and regularly turned with a compost turner for 30-45 days. This achieves fermentation, kills pathogens and weed seeds, and stabilizes nutrients.

- Primary Crushing:The composted material is crushed into a uniform size.

- Ingredient Mixing:The base compost is blended with additives to achieve target NPK values.

- Granulation:The mixed powder is fed into a granulator to form spherical granules.

- Drying & Cooling:Granules are dried to a safe moisture level (<12%) and cooled.

- Secondary Screening:Finished granules are separated into on-size, undersized, and oversized granules. On-size granules are moved to the coating machine while others are recycled back to the crusher.

- Coating & Packaging:A final polish and coating is applied before automated bagging.

Why Choose a Turnkey Solution for Your South African Operation?

For investors and entrepreneurs in South Africa, a LANE turnkey solution provides:

- Single-Point Accountability: One contract, one responsible partner for the entire system’s performance.

- Time & Cost Efficiency: Eliminates project management overhead and delays from coordinating multiple suppliers.

- Optimized System Design: LANE ensures all components are correctly sized and compatible with each other.

- Faster Return on Investment (ROI): Rapid commissioning and smooth start-up mean production and revenue begin sooner.

- Comprehensive Training: LANE trains technicians to operate and maintain the line effectively.

Conclusion: Building a Sustainable Future with LANE

South Africa’s organic fertilizer market is projected to grow at a 7.9% CAGR through 2029. Investing in a high-quality organic fertilizer production line in South Africa is a profitable move that aligns with a growing market. The shift toward organic agriculture is not just a trend but an evolution for South Africa’s food security and environmental health.

Investing in an organic fertilizer production line in South Africa is a strategic move with economic and ecological returns. From production line design to the final bag of premium fertilizer, LANE Heavy Industry can help you achieve your economic and ecological goals.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520