Starting an organic fertilizer production line in Zambia is a visionary business move. Zambia’s economy relies heavily on agriculture, and the demand for high-quality soil conditioners is growing every day. Whether you are dealing with sugar cane waste, chicken manure, or maize stalks, turning organic waste into high-value fertilizer pellets is both environmentally friendly and highly profitable.

At LANE, we have spent over 20 years perfecting the art of fertilizer machinery. We understand that building a factory is not just about buying machines; it is about creating a reliable system that works day in and day out. Our company has grown into a leader in the Chinese fertilizer machinery field because we focus on the small details that make a big difference in production. When you choose to build your organic fertilizer production line in Zambia with us, you are gaining a partner with two decades of deep industry experience.

In the past, many farmers used “raw” manure. However, raw manure can contain pathogens and weed seeds that harm crops. A modern organic fertilizer production line in Zambia uses heat and fermentation to kill these pests while concentrating the nutrients.

This process requires a sequence of specialized machines. As a team that offers one-stop, full-scale services, we ensure that every machine in your line is synchronized. We don’t believe in a “one size fits all” approach. Instead, our professional engineering team works with you to design a production line that fits your specific space, your budget, and the type of waste you have available.

The journey of your organic fertilizer production line in Zambia begins with fermentation. This is where the raw organic matter breaks down into stable compost.

The compost turner is the “muscle” of the fermentation stage. If you just leave a pile of manure sitting, it will rot slowly and smell bad. Our crawler-type compost turner moves through the piles, lifting the material and mixing it with fresh air.

Detailed Function: It facilitates aerobic fermentation. By turning the pile, it ensures that oxygen reaches the bacteria that break down the waste. It also helps control the moisture content by allowing steam to escape.

Our Advantage: With over 20 years of experience, we have refined the blades and the drive system of our turners. They are built to be heavy-duty because we know that Zambian farm environments can be tough. We use high-wear-resistant materials that can handle the constant friction of soil and waste.

Customization: We offer both crawler-type and wheel-type turners depending on your factory floor setup. Our engineers can advise you on which model will maximize your space.

Once the compost is ready, it is usually a bit lumpy and contains various sizes of organic matter. To make a high-quality pellet in your organic fertilizer production line in Zambia, you need a fine, uniform powder.

This is where the fermented material is pulverized. A standard crusher often gets clogged if the compost is even slightly damp. Our vertical crusher is specifically designed to solve this problem.

Detailed Function: It uses a chain or blade system that spins at high speeds. The “new type” design means it doesn’t have a screen at the bottom. Why is this important? Because a screen is usually where wet material gets stuck. Without a screen, the material flows through freely while still being crushed to a fine size.

Our Advantage: Our equipment is built to ISO9001 and CE international quality standards. This means the internal components are balanced perfectly to reduce vibration, which extends the life of the machine. When you buy from us, you are getting a machine that won’t break down in the middle of a busy season.

A successful organic fertilizer production line in Zambia must produce a consistent product. If one bag has more nitrogen than the next, your customers will lose trust.

After crushing, you might want to add “functional” ingredients, like beneficial microbes or small amounts of NPK (Nitrogen, Phosphorus, Potassium) to create a bio-organic blend.

Detailed Function: The mixer uses a large internal shaft with paddles or a screw ribbon. It tumbles the powder until every additive is perfectly distributed.

Our Advantage: We focus on efficiency. Our mixers are designed to have a “low dead zone,” meaning very little material stays in the corners. This prevents cross-contamination between different batches. Our professional engineering team can even automate the feeding system so that the exact weight of each ingredient is added automatically.

This is the most exciting part of the organic fertilizer production line in Zambia. This is where the loose powder is transformed into hard, round, and shiny pellets.

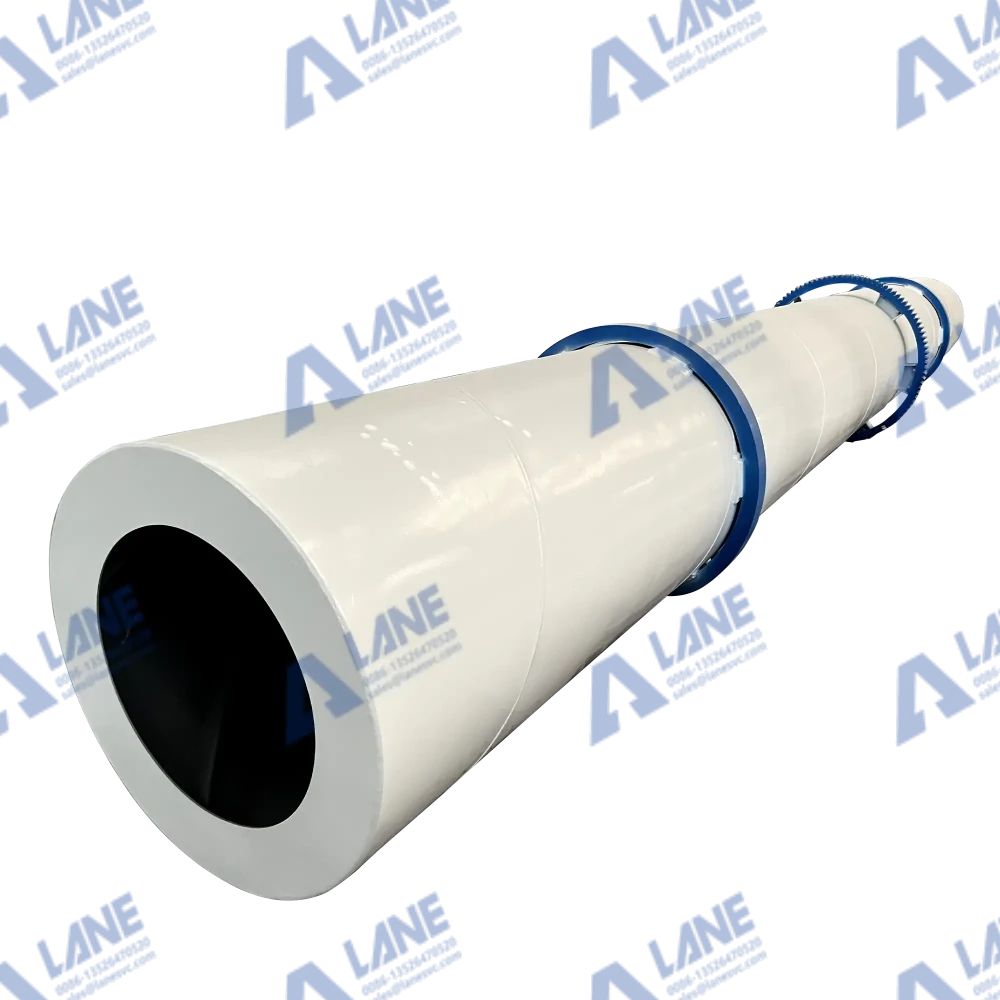

The Rotary Drum Granulator is one of the most popular and reliable choices for large-scale production. It is a masterpiece of engineering that relies on mechanical movement and physics to form perfect pellets.

Detailed Function: Inside the drum, a high-speed stirring shaft hits the powder, and the rotation of the drum itself causes the material to “ball up.” The result is a pellet that is much denser and more uniform than what you would get from a simple disc granulator.

Our Advantage: As a company specializing in organic, compound, and liquid fertilizer machinery, we have seen which granulators work best for different materials. We customize the internal lining and the speed settings based on your specific organic waste. Our granulators have a “balling rate” of over 95%, which means almost all your powder turns into high-quality pellets on the first pass.

When the pellets come out of the granulator, they are warm and have about 20% to 30% moisture. If you bag them now, they will turn back into mush.

These are two large, rotating cylinders that sit at a slight angle.

Detailed Function: The Dryer uses a heat source (like a coal, gas, or biomass furnace) to blow hot air through the tumbling pellets. This removes the moisture. The Cooler then uses ambient air to bring the temperature down quickly. This “shocks” the pellet, making it much harder and more durable.

Our Advantage: Heat efficiency is key in Zambia to keep operating costs low. We design our dryers with internal “lifting plates” that shower the fertilizer through the hot air, ensuring every pellet gets dried evenly without wasting fuel. Our ISO9001 and CE certifications ensure that these high-heat machines are safe for your workers to operate.

To make your product from your organic fertilizer production line in Zambia look professional, it needs to be uniform.

Not every pellet is the same size. Some are too big, and some are too small.

Detailed Function: The screening machine is a rotating drum with different mesh sizes. It separates the “oversized,” the “undersized,” and the “perfect” pellets. The perfect ones move to the next stage, while the others are automatically sent back to the crusher or granulator.

The Coating Machine: Optional but recommended. It adds a thin layer of oil or wax to the pellets to prevent them from sticking together and to give them a professional shine.

Our Advantage: We provide a one-stop full-scale service. This means we design the conveyor belts that link all these machines together. You don’t have to worry about how the material gets from the dryer to the screen; our system handles it automatically.

The final step for your organic fertilizer production line in Zambia is getting the product into bags.

Doing this by hand is slow and inaccurate. Our automatic system does it in seconds.

Detailed Function: You set the weight (e.g., 50kg). The machine fills the bag, weighs it with a digital sensor, and drops it onto a conveyor where a sewing machine seals it shut.

Our Advantage: Our after-sales support includes training your team on how to calibrate these scales. We want to ensure that your customers in Zambia get exactly what they pay for, every single time.

Setting up an organic fertilizer production line in Zambia is a journey, and we want to be your guide. Here is why we are different:

20+ Years of Professional Experience: We have survived and thrived in the fertilizer machinery industry for over two decades. We have seen technology change, and we have stayed at the cutting edge. This deep knowledge allows us to anticipate problems before they happen.

Customization and Engineering: We don’t just sell you a machine; we design a factory. Our professional engineering team can provide you with CAD drawings and 3D layouts of your organic fertilizer production line in Zambia. We make sure the workflow is efficient, reducing the number of workers you need.

One-Stop Service: From the moment we sign a contract, we handle everything. We manufacture the machines, arrange the shipping to Zambia, and send our engineers to your site to install the equipment. Our service includes maintenance, troubleshooting, and even future upgrades.

International Quality Standards: Our commitment to quality is proven by our ISO9001 and CE certifications. We use high-quality motors, bearings, and steel. Our machines are built for a 10-to-15-year lifespan, not just a couple of seasons.

Full After-Sales Support: We know that a machine is only useful if it is running. That is why we provide comprehensive after-sales support. If you need a spare part or have a technical question about your organic fertilizer production line in Zambia, our team is always ready to help.

The agricultural potential of Zambia is massive. By installing an organic fertilizer production line in Zambia, you are positioning yourself at the center of a sustainable and profitable industry. You are helping farmers increase their yields and helping the country reduce its reliance on expensive imported chemical fertilizers.

At LANE, we are proud to offer the most reliable, efficient, and professional machinery on the market. We have the experience, the certifications, and the passion to make your project a success. We don’t just build machines; we build the future of farming.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520