Organic fertilizer is the poster child of sustainable agriculture. Because of the increased demand for organically produced food and increased soil health awareness, farmers are using organic fertilizers instead of synthetic fertilizer. This creates an opportunity for investors and agribusinesses to start an organic fertilizer project.

The organic fertilizer project aims to convert organic wastes, such as animal manure, crop straw, and food residues into high-quality organic fertilizer. This business plan outlines a roadmap for establishing a profitable and scalable organic fertilizer project. By converting agricultural, municipal, and livestock waste into high-value organic fertilizer, this project delivers environmental impact and strong financial returns.

The global organic fertilizer market is experiencing robust growth. It is driven by consumer awareness, government policies promoting sustainable agriculture and recognition of long-term soil health benefits. The overuse of chemical fertilizers has degraded soils. It has created a pressing need for organic alternatives that rebuild soil structure and microbial life.

Target customers for organic fertilizer include:

Your organic fertilizer project positions itself at the intersection of environmental sustainability and agricultural productivity. The market for organic fertilizer has a compound annual growth rate (CAGR) of 8% annually.

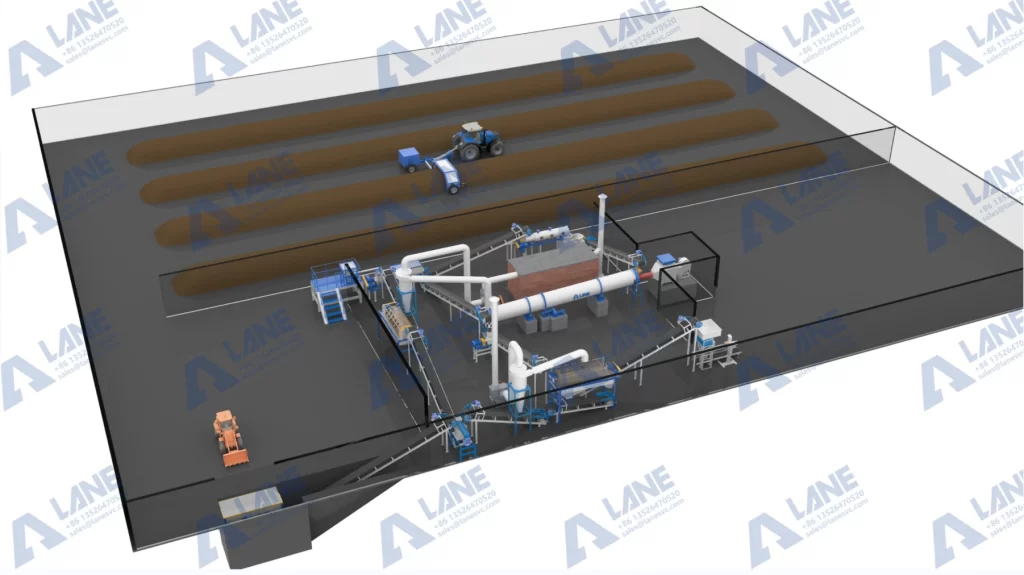

The efficiency and quality of your organic fertilizer project depend on your production technology and raw material consistency. A semi-automated or fully automated line from LANE Heavy Industry provides a complete solution. Here’s how the machinery integrates into the production workflow:

Investing in an automatic organic fertilizer production line minimizes labor, ensures consistency, and maximizes output.

A reliable, low-cost supply of consistent raw materials is crucial. Potential sources include:

Establishing collection agreements or partnerships turns these waste products into your primary feedstock, which is a foundational step in any Organic Fertilizer Project. This approach is critical for securing a stable supply chain while keeping raw material costs to a minimum.

You must decide on your business model. Will the project operate on a B2B or B2C model or a hybrid model with multiple revenue streams?

Initial Investment (Estimated):

Projected Monthly Revenue (Year 2):

With operational costs (materials, labor, utilities, marketing) estimated at 60%, the monthly net profit could reach $25,000, indicating a potential ROI within 12-18 months of full operation. These figures are illustrative and depend on scale, location, and market prices.

Q1: How profitable is an organic fertilizer project?

A: Profitability is strong due to low-cost waste inputs and high-demand outputs. Margins typically range from 30–50%, depending on scale, efficiency, and sales channels. For any Organic Fertilizer Project, the key lies in efficient production processes and effective marketing strategies.

Q2: Why is LANE Heavy Industry machinery recommended for this project?

A: LANE provides integrated, durable equipment designed specifically for organic fertilizer production. Their complete lines ensure seamless processing from raw waste to packaged product, reducing technical hurdles and ensuring consistent, marketable granule quality—an essential factor for the long-term success of an Organic Fertilizer Project.

Q3: Is organic certification necessary, and how do I get it?

A: For selling to commercial organic farms, certification is essential. It involves applying to a certifying body, submitting your production plan (including LANE equipment processes and input sourcing), and passing an annual inspection. Certification adds credibility and allows an Organic Fertilizer Project to command premium prices in competitive markets.

Q4: What are the biggest challenges in starting this business?

A: Key challenges include securing consistent raw material supply, managing the composting process (odors, time), navigating local environmental regulations, and building initial market trust. A solid business plan and quality equipment from partners like LANE Heavy Industry mitigate these risks.

Q5: Can this project start on a small scale?

A: Absolutely. Many successful projects begin with a minimal LANE setup (e.g., a turner, crusher, and granulator), processing local manure. This allows for testing the market and refining the process before investing in a full automated line for scaling up.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520