For commercial growers and manufacturers, consistent quality is the foundation of trust and crop success. Effective organic fertilizer quality control is a systematic project. It is a continuous, multi-stage process that ensures every bag of product is safe, potent, and reliable. Henan Lane Heavy Industry Machinery Technology Co., Ltd., a leader in fertilizer production equipment, provides reliable technical support throughout the production process.

Organic fertilizer quality control determines the final product’s safety, efficacy, and compliance with regulators. From feedstock screening to final packaging, strict quality management ensures products meet the latest Organic Fertilizer (NY/T 525-2021) standard.

This article provides the outline of the critical stages where control protocols must be applied.

The organic fertilizer quality control begins long before production starts. The quality of the final product is directly linked to the preparation of the raw materials used, such as animal manures, plant residues, or food waste.

Supplier Verification: Reputable producers always audit their feedstock suppliers. This ensures that the raw materials come from reliable, traceable sources and the raw materials are free from prohibited contaminants.

Initial Testing: Upon receiving the raw material, it must immediately be inspected and tested. It will help you determine the moisture content, foreign matter (e.g., plastics, metals), and obvious contamination. An advanced factory by LANE contains a testing lab for rapid tests for heavy metals or unwanted pathogens.

This stage prevents poor quality raw material from entering the production and prevents contamination of other raw materials. It is the first and most important defense line in organic fertilizer quality control.

In the fertilizer industry, consistency separates the good fertilizer manufacturer from the bad fertilizer manufacturer. This stage involves preparing and blending raw materials to create a uniform recipe with targeted nutrient ratios, which is a key aspect of organic fertilizer quality control.

Shredding and Mixing: LANE fermentation tanks ensure a homogenous particle size and blend. They are equipped with precise stirring and temperature control systems. Consistent texture is crucial for predictable decomposition and nutrient release. LANE Heavy Industry’s engineering in this area focuses on creating a fermentation system that will create an odorless premium quality compost while supporting organic fertilizer quality control standards.

Recipe Adherence: Based on the lab analysis of the feedstock, specific materials are blended to achieve desired NPK values and carbon-to-nitrogen ratios. This step ensures the batch-to-batch consistency of the end granulated product.

This is where the active production of the organic fertilizer begins. In this stage, biological activity transforms raw waste into stable humus.

Monitoring Critical Parameters: In this stage, temperature, moisture, and aeration must be constantly monitored and managed. One mistake will reduce the quality of the product or extend the fermentation time.

Temperature: It must reach and maintain 60-67°C. This temperature is sufficient to kill weed seeds and pathogens without harming the beneficial microbes.

Moisture & Aeration: Moisture must be at optimal levels, usually it’s 50-60%. This ensures efficient aerobic decomposition without odors. LANE fermentation tanks and LANE compost turners are crucial for this stage.

Pathogen Reduction: The most important steps of this stage are pathogen reduction. By effectively controlling the temperature curve, the operator can kill pathogens while maintaining safety and certification compliance.

After fermentation, the composted or fermented raw materials need to go through the ageing process. In this process, the composted/fermented compost is stored in a dry place where it is turned three or four times a week with LANE Compost turners.

After stabilization, the composted material is prepared for granulation.

Curing and Stabilization: In this stage, material is cured by the process of ageing. This allows the microbial activity to stabilize. It prevents the nitrogen drawdown in the soil.

Crushing and Granulation: The composted raw materials are sent to the main production line. They are entered through the Dynamic batching system. This hopper is equipped with a weighting scale and sensors. It controls the release of raw materials. Next, the raw materials are sent to the LANE Vertical crusher where it is made into fine powder.

After that, the products are sent to the Stirring pin granulator for the granulation process. This is a new style granulator which has a granulation rate of 85 to 97%.

Polishing: After granulation, the product needs to be polished. LANE’s polishing machine uses rotation and friction to make the granules rounder. At this stage, the granules are prone to caking.

Drying and Cooling: At this stage, the granules are sent to the drying machine to dry the moisture of the granules to prevent it from caking. After the drying process is done, it needs to be cooled to prevent breaking and reduce the temperature for packing to increase the shelf life.

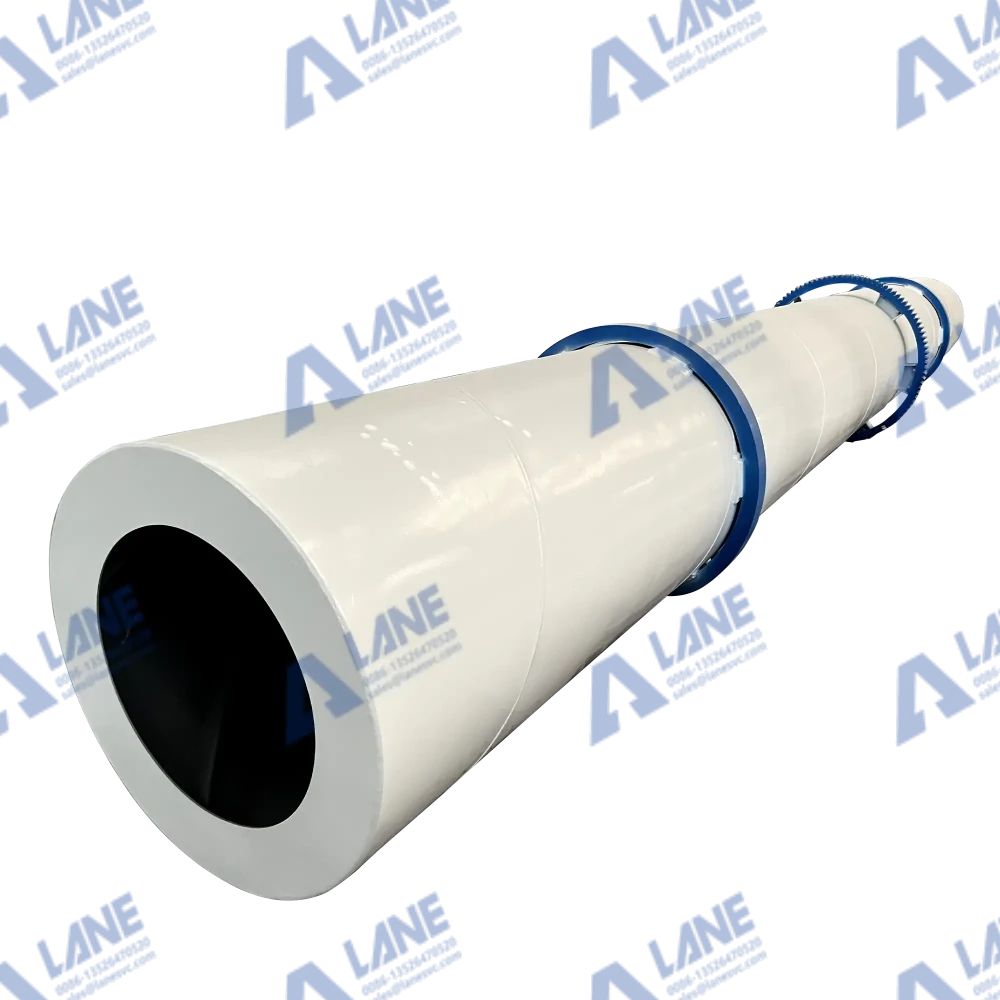

Screening: LANE rotary screen is used in this stage to separate the on-size granules from the dust particles and other sized granules. The on-size granules are sent to the packing machine while other products are sent to the crusher to reenter the production.

Before packing, the finished product must undergo one last testing to ensure the consistency of the products. This is the most data-driven stage of organic fertilizer quality control.

This stage makes sure that the products are indeed maintaining the quality standard according to recipes.

LANE packing is an automated process where the packing machine automatically weighs the products and packages them. The whole process is touch-free so there is no chance of contaminating the final products.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520