With the rapid growth of eco-friendly agriculture, more attention is being paid to organic waste reuse. One practical solution is learning how to produce organic fertilizer granules from vinegar residue in a stable and efficient way. Vinegar residue, also known as vinegar lees, is a by-product of vinegar production. For a long time, it was difficult to handle and costly to dispose of.

However, this material is rich in organic matter and beneficial nutrients. When processed properly, vinegar residue can become a valuable input for soil improvement. Instead of being a burden, it becomes part of a sustainable agricultural cycle.

Soil degradation is a common challenge in modern farming. Long-term use of chemical fertilizers often reduces organic content and microbial activity. Vinegar residue offers a natural way to reverse this trend.

First, it improves soil structure. Organic matter from vinegar residue helps loosen compacted soil, improving water retention and air circulation. Roots grow more freely, and crops become more resilient.

Second, it supports soil microorganisms. These microorganisms play a key role in nutrient conversion. When farmers produce organic fertilizer granules from vinegar residue, they create a stable food source for beneficial microbes, which helps maintain long-term soil fertility.

Third, it contributes to balanced nutrient release. Unlike chemical fertilizers that act quickly but fade fast, organic fertilizer made from vinegar residue releases nutrients slowly and steadily.

Raw vinegar residue is not suitable for direct field use. It has high moisture, uneven texture, and poor storage performance. This is why granulation is so important.

When producers produce organic fertilizer granules from vinegar residue, the material becomes dry, uniform, and easy to spread. Granules improve application efficiency and reduce labor costs. They also reduce odor and improve product appearance, which is important for commercial sales.

Granular fertilizer is easier to transport and store, making it more practical for large-scale agriculture and long-distance markets.

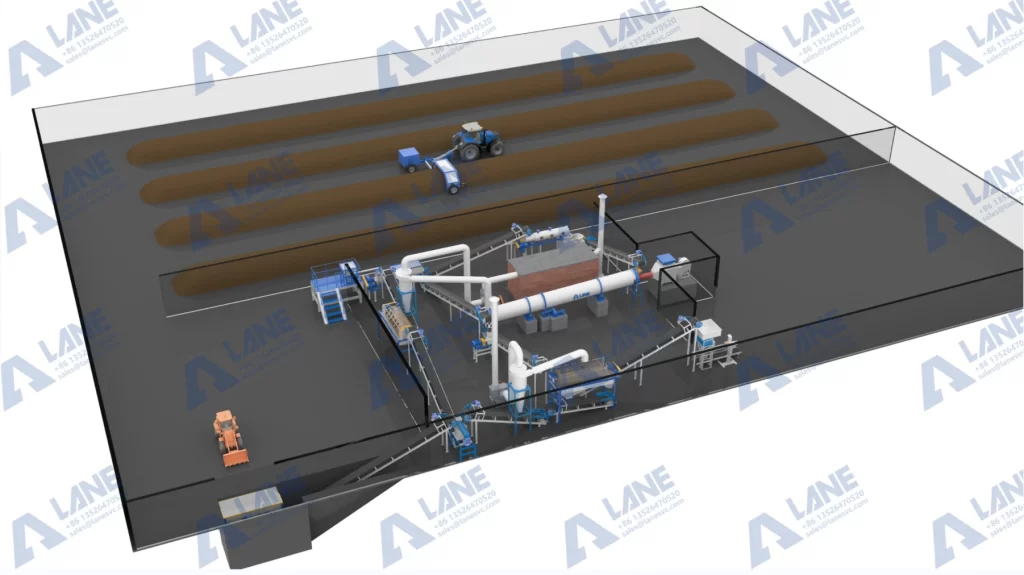

The overall process to produce organic fertilizer granules from vinegar residue is clear and logical. First, raw materials are prepared and moisture is adjusted. Then fermentation improves safety and stability. After that, granulation shapes the material, followed by drying, cooling, and screening.

Each step works together to ensure the final product is stable, safe, and effective for soil use.

To successfully produce organic fertilizer granules from vinegar residue, a clear and reliable equipment setup is essential.

The process usually starts with a chain crusher or hammer crusher, which crushes dried vinegar residue and other organic materials into a uniform size.

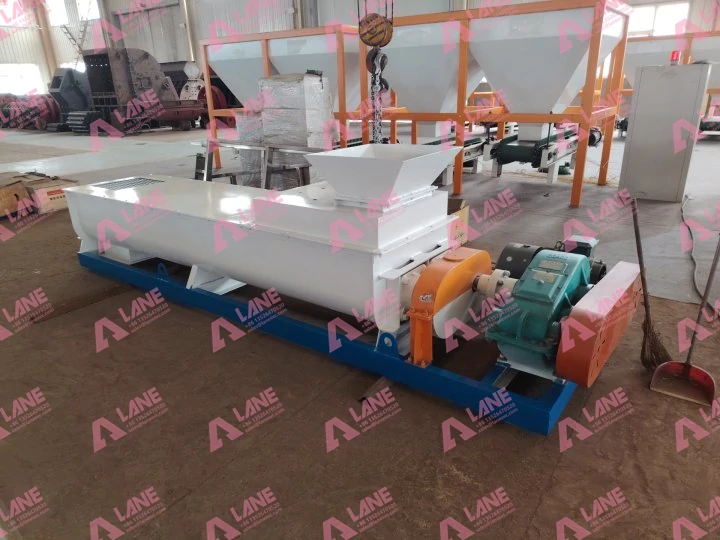

Next, a horizontal mixer or double-shaft mixer is used to mix vinegar residue with auxiliary organic materials evenly. This ensures consistent quality before granulation.

The core equipment is the organic fertilizer granulator, commonly including a disc granulator, rotary drum granulator, or new-type organic fertilizer granulator. These machines shape the material into round, uniform granules and are central to any system designed to produce organic fertilizer granules from vinegar residue.

After granulation, a rotary dryer reduces moisture content and improves granule strength. The hot granules then move into a rotary cooler, which lowers temperature and prevents caking.

A rotary screening machine separates qualified granules from unqualified ones. Oversized or undersized particles are returned to the granulation stage.

Finally, an automatic packaging machine weighs and packs finished fertilizer, making storage and transportation more convenient.

Organic fertilizer made from vinegar residue is suitable for vegetables, fruit trees, field crops, and greenhouse planting. Farmers value it for its soil-improving effect and long-term benefits.

As sustainable agriculture continues to grow, more producers want to produce organic fertilizer granules from vinegar residue to meet rising market demand. At the same time, vinegar factories benefit by reducing waste treatment costs, creating opportunities for cooperation.

At LANE, we have more than 20 years of experience in fertilizer machinery manufacturing. We help customers worldwide produce organic fertilizer granules from vinegar residue through practical, proven solutions.

We have a professional engineering team that designs customized equipment and complete production lines based on customer needs. From layout planning to equipment installation, we focus on efficiency and long-term stability.

We also provide one-stop service, including installation guidance, technical training, after-sales support, maintenance, and equipment upgrades. Our goal is to keep production lines running smoothly over time.

Quality and reliability are key to fertilizer production. Our equipment meets international standards such as ISO9001 and CE, ensuring stable performance and safe operation.

We specialize in fertilizer production lines, including organic fertilizer equipment, NPK production lines, and compound fertilizer equipment. This complete product range allows us to support customers at different production scales and help them confidently produce organic fertilizer granules from vinegar residue.

Turning vinegar residue into organic fertilizer is a smart and responsible choice. It reduces waste, improves soil health, and creates real economic value.

With the right process and reliable equipment, it is easier than ever to produce organic fertilizer granules from vinegar residue and support sustainable agriculture. At LANE, we are ready to share our experience and support every step of your production journey.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520