More people today want to produce plant-based organic fertilizer granules, but they often meet the same problems again and again. Some cannot control moisture, some don’t know which machines to use, and some feel the whole process is too complicated. For many beginners, even simple things like mixing or drying can become difficult. And without the right setup, it’s hard to produce plant-based organic fertilizer granules that are strong, clean, and good enough to sell.

Plant-based materials such as crop leaves, bean waste, seaweed, or mushroom leftovers are rich in organic matter. They are helpful for the soil, but they are not always easy to turn into granules. Some are too wet, some are too dry, and some have fibers that cause the granules to fall apart. But once you understand the basic steps, it becomes much easier to produce plant-based organic fertilizer granules in a simple and steady way.

In this article, we will walk through a clear and easy process using simple language. You will learn each step, from crushing to packaging. We will also explain what machines are needed, why they matter, and how a smooth production line can help you produce plant-based organic fertilizer granules with less effort and better results.

Plant-based raw materials are not the same every time. Some batches may have higher water levels, some may contain long fibers, and some may smell stronger. If these parts are not handled well, the granules may become soft or crumble. This is why many producers struggle to produce plant-based organic fertilizer granules that look clean and stay firm during storage.

The key is to keep the material uniform. When the material is even in size and moisture, the rest of the work becomes easier. Without this step, no machine can help fix the problem later. So the whole process must be steady, simple, and well connected.

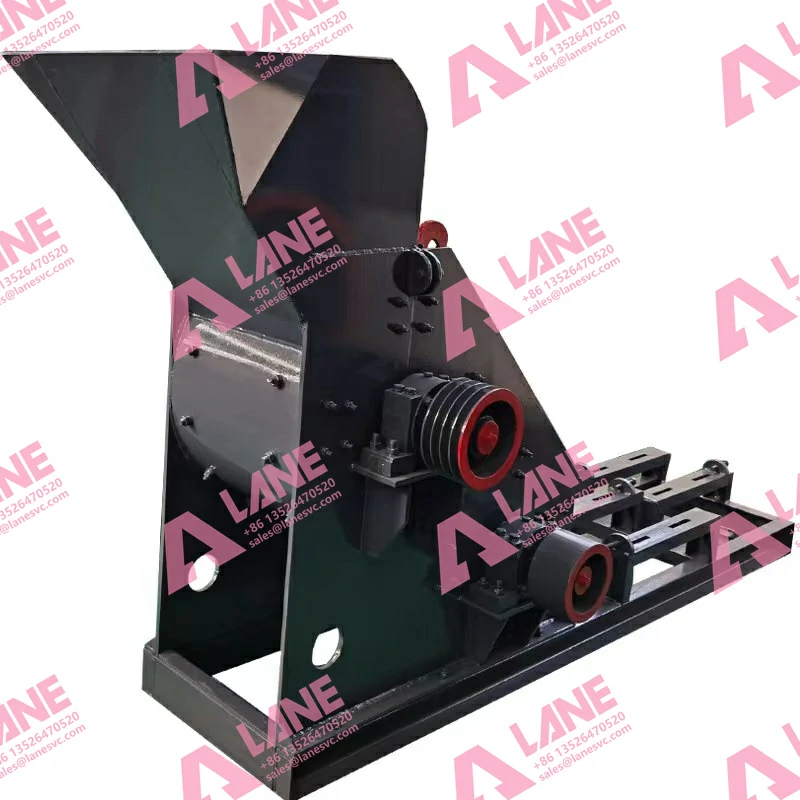

If you want to produce plant-based organic fertilizer granules that are round and strong, the first step is crushing. A hummer crusher can break plant materials into small pieces. This makes the next steps smoother.

Plant fibers are often long or hard. A hammer crusher helps turn them into soft, fine pieces. This helps fermentation, mixing, and granulation. After crushing, the material looks more even and is easier to handle.

Fermentation is a natural process that makes plant-based materials stable and safe to use. A crawler compost turner helps move and mix the material so it gets enough air. Good fermentation usually takes a couple of weeks, depending on the material.

You don’t need to understand complicated science. Just remember: fermented material is softer, cleaner, and easier to turn into granules. Without this step, it’s hard to produce plant-based organic fertilizer granules that stay solid and last long on the shelf.

After fermentation, different materials need to be mixed well. A simple horizontal mixer can help blend everything together. This step is important because each granule needs to contain similar nutrients.

At this stage, water is also adjusted. Moisture plays a big role when you try to produce plant-based organic fertilizer granules. If the material is too wet, granules will not form well. If it is too dry, granules will break apart. A mixer helps you reach the right balance.

Granulation is the heart of the whole process. This is where you finally produce plant-based organic fertilizer granules in the shape you want. There are different granulators to choose from, and each has its own advantages.

The choice depends on your raw materials and production scale. Many producers prefer the new type granulator because it works well with different plant-based materials and gives a high granulation rate.

If your goal is to produce plant-based organic fertilizer granules quickly and with steady quality, choosing the right granulator makes a huge difference.

Fresh granules usually contain more water than needed. A rotary dryer helps remove this extra moisture. Dry granules are stronger and do not go bad in storage.

Drying is very important if you want to produce plant-based organic fertilizer granules that can be packed, shipped, and sold widely. Without drying, granules may break or grow mold.

After drying, the granules are hot. A rotary cooler brings down the temperature so the granules do not crack. Cooling makes the granules strong and clean.

This step is simple but necessary. Many producers skip cooling and later find their granules breaking in bags. Proper cooling helps the granules stay in good shape.

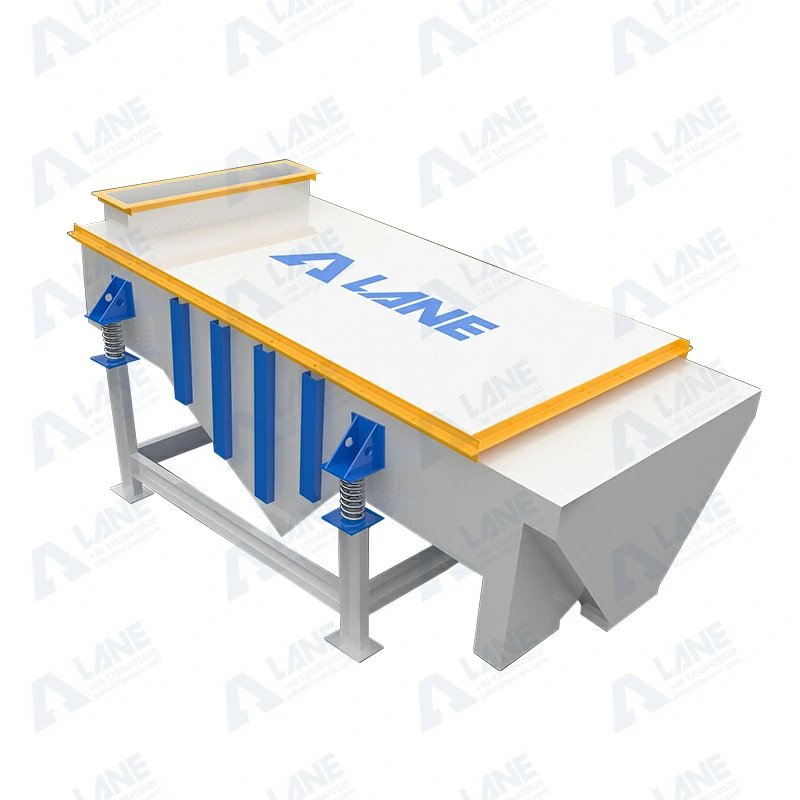

A vibration screen machine helps divide the granules into three groups:

The unqualified ones can be crushed and reused. This helps you produce plant-based organic fertilizer granules with a neat, uniform look.

Once everything is done, an automatic packing machine fills bags with the final granules. Packed granules are easier to store and move.

A clean and simple packing step gives your product a good appearance and helps build trust with customers.

To make everything clear, here is the basic equipment used in the process:

With these machines working together, producers can easily produce plant-based organic fertilizer granules day after day with steady performance.

Many customers tell us that the hardest part is not learning how to produce plant-based organic fertilizer granules, but building a production line that actually works well. This is where our team comes in.

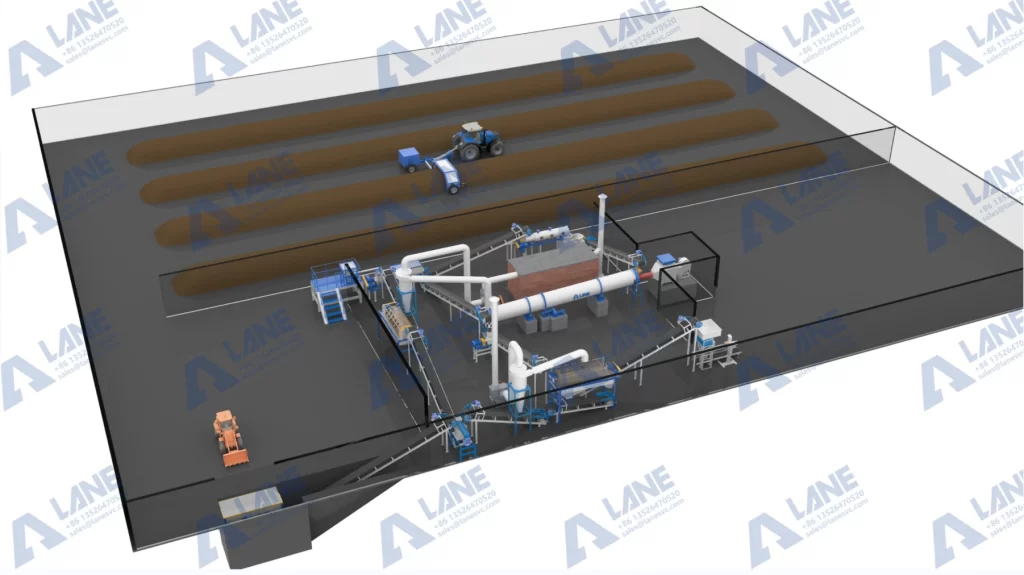

LANE has been making fertilizer machines for over 20 years. Our engineers help design full production lines based on your raw materials, your land size, and your production plan. We don’t just ship machines—we help you set them up, test them, and make sure they run smoothly.

Our company follows strict international quality standards, so the machines are stable, safe, and long-lasting. We also provide continued support after installation. If you ever need help with maintenance, operation, or upgrades, our team is ready to step in. Many producers say this long-term support gives them confidence to grow their business and continue to produce plant-based organic fertilizer granules without worry.

Whether you need a small line or a large factory setup, we focus on giving you practical, easy-to-use solutions that match plant-based fertilizer production. With LANE, you get a partner who understands the full process from start to finish.

Learning to produce plant-based organic fertilizer granules is not as hard as it seems. With clear steps, simple machines, and reliable support, anyone can turn plant waste into valuable organic fertilizer.

A good production line reduces work, saves time, and helps you create clean, strong granules that customers trust. And with the right help, especially from experienced manufacturers like LANE, you can confidently produce plant-based organic fertilizer granules with better quality and higher efficiency.

If you plan to start or upgrade your production, now is a great time to begin. Plant-based fertilizer has a strong future, and a well-designed production line will help you grow with it.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520