With the fast growth of eco-friendly agriculture, more farms are looking for simple and reliable ways to recycle animal waste. A rabbit manure organic fertilizer production line is a smart solution. Rabbit manure is rich in organic matter and nutrients, and it is easy to process when the right equipment is used.

In this article, we explain the full production flow in a clear and friendly way. You will see what equipment is needed at each stage, how the machines work with the material, and why every step matters in a complete rabbit manure organic fertilizer production line.

The process starts with collecting fresh or semi-dry rabbit manure. At this stage, the material may still contain moisture, bedding material, or small impurities.

The main equipment used here includes:

Feeding hopper

Belt conveyor

The feeding hopper stores rabbit manure and sends it evenly into the next process. The belt conveyor moves the material smoothly, reducing labor and keeping the workflow stable. In a modern rabbit manure organic fertilizer production line, this step ensures continuous feeding and avoids blockages later on.

Fermentation is one of the most important steps. It removes harmful bacteria, reduces odor, and improves fertilizer quality.

Common equipment includes:

Compost turner

Fermentation tank (optional)

The compost turner regularly flips the manure, allowing air to enter the pile. This helps good bacteria grow and speeds up decomposition. During fermentation, temperature and moisture are controlled naturally through turning. In a well-designed rabbit manure organic fertilizer production line, fermentation usually takes several days to a few weeks, depending on conditions.

After fermentation, the material may still be in large clumps. Crushing helps create a finer and more even texture.

Typical machines:

Organic fertilizer crusher

Chain crusher or hammer crusher

The crusher breaks fermented manure into small particles. This step improves mixing quality and prepares the material for granulation. A reliable crusher keeps particle size consistent, which is key for smooth operation in the next stages of the rabbit manure organic fertilizer production line.

At this stage, additional materials such as straw powder, humic acid, or beneficial microbes may be added.

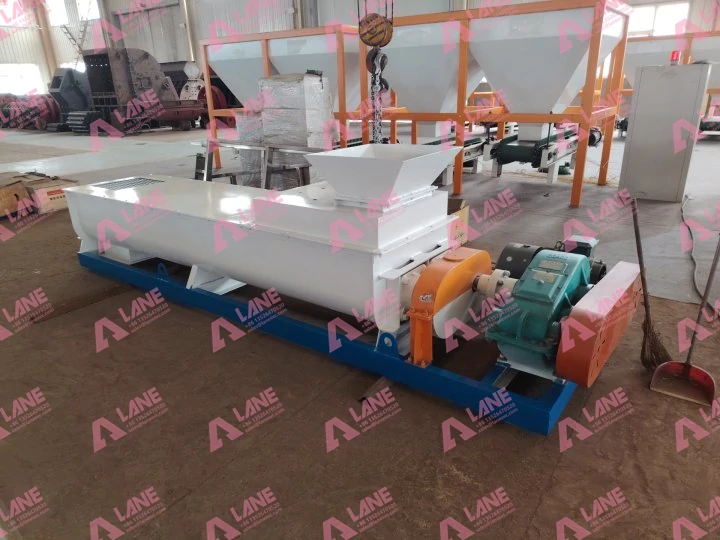

Main equipment:

Horizontal mixer

Double-shaft mixer

The mixer blends rabbit manure with additives evenly. Good mixing ensures each fertilizer granule has balanced nutrients. In a flexible rabbit manure organic fertilizer production line, mixing formulas can be adjusted based on soil needs or market demand.

Granulation turns powder into easy-to-use pellets. This improves storage, transport, and application.

Common granulators:

The granulator uses rotation and moisture to form round pellets. The material sticks together naturally without chemical binders. In a complete rabbit manure organic fertilizer production line, this step greatly improves the product’s appearance and market value.

Fresh granules often contain excess moisture and heat. Drying and cooling make them strong and stable.

Main machines:

Rotary dryer

The dryer uses hot air to reduce moisture to a safe level. After drying, the cooler lowers the temperature to prevent clumping. Proper drying and cooling help granules keep their shape, an essential part of any stable rabbit manure organic fertilizer production line.

Not all granules are the same size after granulation. Screening helps separate qualified products from oversized or undersized ones.

Equipment used:

Rotary screening machine

The screen sorts granules by size. Qualified pellets move forward, while others are returned for re-crushing and re-granulating. This recycling loop improves efficiency in the rabbit manure organic fertilizer production line and reduces waste.

Coating is optional but useful for higher-end fertilizer products.

Main machine:

Fertilizer coating machine

The coating machine applies a thin layer of oil or functional liquid to the granules. This reduces dust, improves appearance, and can add slow-release properties. In premium rabbit manure organic fertilizer production line projects, coating helps products stand out in the market.

The final step is weighing and packing the finished fertilizer.

Key equipment:

Sewing or sealing machine

The packing system measures each bag accurately and seals it for storage or transport. Good packaging improves brand image and makes handling easier. At this point, the rabbit manure organic fertilizer production line has completed the full transformation from waste to product.

At LANE Heavy Industry, we have focused on fertilizer equipment manufacturing for over 20 years. Our experience allows us to understand real production needs, not just machine design. We don’t believe in one-size-fits-all solutions.

Our professional engineering team works closely with customers. We design, manufacture, install, and test complete production lines based on site conditions and output goals. Whether you need a compact system or a large-scale rabbit manure organic fertilizer production line, we can customize it for you.

We also provide one-stop service, including installation guidance, operator training, and long-term after-sales support. Maintenance, troubleshooting, and future upgrades are all part of our service promise. Our equipment meets ISO9001 and CE quality standards, ensuring stable operation and reliable performance.

Building a successful rabbit manure organic fertilizer production line is not complicated when each step is clearly planned. From fermentation to packaging, every machine plays a clear role in turning rabbit manure into a valuable organic fertilizer.

With the right equipment and a professional partner, rabbit manure can become a steady source of income and support sustainable agriculture. At LANE Heavy Industry, we are ready to help you build an efficient, reliable, and future-proof production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520