Rice is one of the most widely cultivated crops in the world, and during its production process, a large amount of straw is generated. Traditionally, farmers often burned the straw in the fields, causing severe air pollution and resource waste. However, with the help of modern composting and fertilizer production technologies, the straw can be transformed into valuable resources.

A rice straw compost fertilizer line offers an environmentally friendly and cost-effective way to recycle agricultural waste. By processing straw into high-quality compost fertilizer granules, farmers and agribusinesses can improve soil health, reduce dependency on chemical fertilizers, and generate additional income.

1.Why Compost Rice Straw Instead of Burning It?

Environmental Protection: Burning rice straw releases carbon dioxide, particulate matter, and other pollutants. Composting avoids harmful emissions.

Soil Improvement: Compost made from rice straw enriches soil organic matter, improves structure, and enhances microbial activity.

Nutrient Recycling: Rice straw contains valuable nutrients such as nitrogen, potassium, and silica, which can be returned to the soil through composting.

Regulatory Pressure: Many countries are restricting open-field burning of crop residues, encouraging farmers to adopt composting technologies.

Economic Value: Processed into fertilizer granules, rice straw becomes a marketable product, creating a new revenue stream for producers.

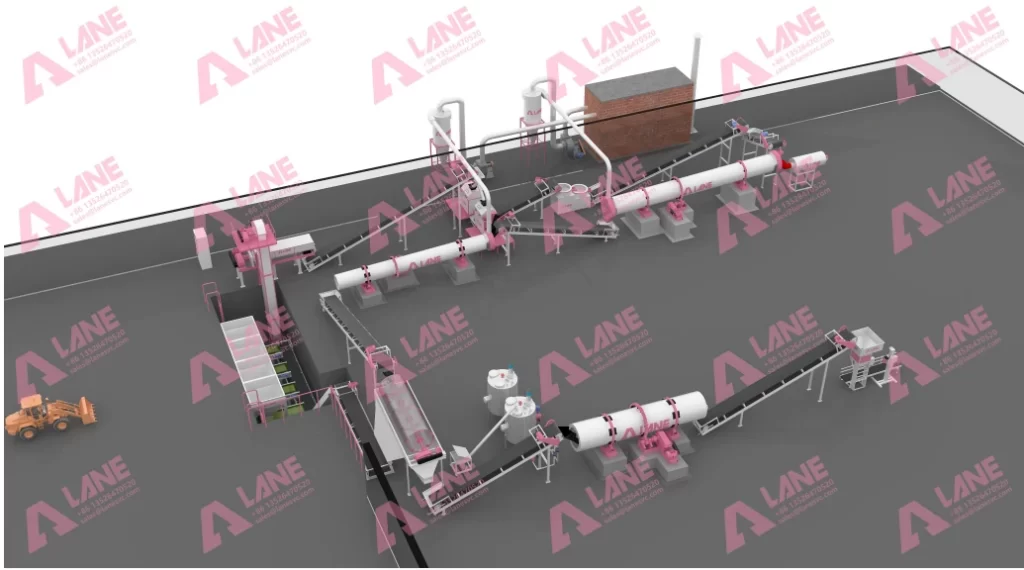

2.Workflow of a Rice Straw Compost Fertilizer Line

The rice straw compost fertilizer line is designed to transform agricultural residues into high-quality organic fertilizer granules through a systematic and efficient process. Each stage is carefully managed to maximize nutrient retention, ensure product stability, and minimize environmental impact.

1.Straw Collection and Crushing

Rice straw is collected directly from the fields after harvest. Since straw is bulky and fibrous, it is first fed into a shredding machine that cuts it into smaller pieces (typically 3–5 cm). This step improves material aeration, accelerates microbial decomposition, and reduces the risk of uneven composting.

2.Composting and Fermentation

The shredded straw is combined with nitrogen-rich materials such as livestock manure, poultry litter, or food waste to balance the carbon-to-nitrogen ratio. The mixture is then piled into windrows or composting tanks. Using equipment such as the crawler type compost turner or wheel type compost turner, the material is turned regularly to maintain optimal oxygen levels and uniform temperature. During this stage, harmful pathogens and weed seeds are destroyed while beneficial microbial activity thrives, producing stable, odor-free compost.

3.Crushing and Mixing

Once fermentation is complete, the composted material often contains clumps that need to be broken down. A crusher reduces these lumps into finer particles, making them easier to process. Immediately afterward, the material is fed into a horizontal mixer, where it is blended with additives such as trace minerals, beneficial microbes, or conditioners. This integrated step ensures particle uniformity and nutrient balance, preparing the compost for the granulation stage.

4.Granulation

The mixed material is processed into uniform granules using machines such as rotary drum granulator or stirring pin granulator. Granulation improves the handling, application, and storage properties of the fertilizer, while also enhancing its commercial value.

5.Drying and Cooling

Freshly granulated fertilizer contains excess moisture, which can cause caking or microbial instability if left untreated. A rotary drum dryer reduces the moisture content to safe levels, while a rotary drum cooler lowers the temperature of the granules to ensure stability and prevent clumping.

6.Screening and Polishing

The cooled granules are passed through a rotary screener to separate qualified products from oversized or undersized particles. Any rejected granules can be recycled back into the production process. A polishing machine may also be used to smooth the surface of the granules, enhancing their appearance and market appeal.

7.Packaging and Storage

The final product is weighed, bagged, and sealed using an automatic packaging system. Packaging can range from small retail bags (e.g., 5–10 kg) to bulk sacks for industrial agriculture. Proper packaging ensures easier handling, longer storage life, and efficient distribution.

3.Challenges in Rice Straw Management

Rice straw disposal has long been a challenge for farmers across Asia, Africa, and parts of Europe. Open burning remains the most common method because it is cheap and fast. However, this practice creates severe air pollution, smog, and greenhouse gas emissions. Governments in countries like India, Vietnam, and China have even introduced strict regulations and penalties to curb this method.

Another challenge lies in the fibrous nature of rice straw. Its high silica content makes it slow to decompose if not properly shredded and composted. Without adequate equipment, farmers often find it impractical to recycle straw on a large scale. Here, the rice straw compost fertilizer line provides a structured, mechanized solution that addresses both environmental concerns and technical difficulties.

4.Integration with Circular Agriculture

A rice straw compost fertilizer line does more than just recycle waste; it fits neatly into the broader vision of circular agriculture. Instead of treating straw as a problem, it is transformed into a resource that closes the nutrient loop:

Crop Residues to Soil Nutrition: The nutrients contained in rice straw are returned to the soil, enhancing fertility for the next planting cycle.

Waste to Marketable Products: Farmers and cooperatives can sell compost fertilizer, creating new income streams.

Partnership with Livestock Farms: Straw can be composted together with manure, solving two waste issues simultaneously while producing richer organic fertilizer.

Energy and Carbon Credits: Facilities that process rice straw into compost may also benefit from carbon-reduction credits or renewable energy integration, boosting long-term sustainability.

This integration not only promotes better soil health and crop yields but also supports government sustainability initiatives and enhances the resilience of farming communities. It can be seen that this rice straw compost fertilizer line is your best choice.

5.Advantages of Rice Straw Compost Fertilizer Line

Efficient Utilization of Agricultural Waste

Rice straw is produced in massive quantities during the harvesting season, and improper disposal (such as open burning) often leads to serious air pollution. By using a rice straw compost fertilizer line, farmers can recycle this biomass resource into high-quality fertilizer, creating a sustainable waste-to-value cycle.

Improvement of Soil Fertility and Structure

Compost made from rice straw contains abundant organic matter and essential nutrients. Regular application of this organic fertilizer improves soil aeration, enhances water retention capacity, and restores degraded farmland. Compared to chemical fertilizers, compost adds humus that builds long-term soil fertility.

Economic Benefits for Farmers and Agribusinesses

Reduces reliance on expensive chemical fertilizers.

Creates additional income opportunities by selling composted fertilizer.

Utilizes low-cost raw materials (straw, manure, crop residues), resulting in a higher profit margin.

Scalable and Flexible Production

The rice straw compost fertilizer production line can be customized for different capacities. From small-scale local projects to large-scale industrial plants, equipment can be adapted to meet diverse production needs, ensuring flexibility and high output.

Eco-Friendly and Sustainable

Reduces carbon emissions by preventing straw burning.

Supports sustainable agriculture by promoting the use of organic fertilizers.

Aligns with global goals of reducing environmental pollution and enhancing resource efficiency.

High Automation and Easy Operation

With the development of automated compost turners, granulators, and packaging systems, the rice straw compost fertilizer line requires less manual labor while maintaining consistent quality, making it suitable for modern large-scale agriculture.

6.Market Prospects

The market potential of rice straw compost fertilizer lines is very promising, driven by multiple global trends:

Rising Demand for Organic Fertilizers

Consumers worldwide are increasingly turning toward organic foods and sustainable farming. This has led to a surge in demand for organic fertilizers, which are considered safer, more eco-friendly, and better for long-term soil health.

Government Policies and Subsidies

In many countries (such as India, China, and Southeast Asia), governments actively promote straw recycling projects and provide financial incentives for composting facilities. This creates a favorable business environment for companies investing in rice straw compost fertilizer lines.

Large Resource Base

Asia alone produces over 700 million tons of rice straw annually. Even if a small percentage of this straw is converted into compost fertilizer, the market size is enormous. This ensures a continuous supply of raw materials and reduces production costs.

Global Sustainability Goals

International organizations and environmental agencies are encouraging circular economy practices. A rice straw compost fertilizer line directly contributes to these goals by reducing waste, cutting emissions, and producing eco-friendly fertilizers.

Investment and Export Opportunities

The fertilizer industry is not limited to local markets. High-quality organic fertilizers produced by rice straw composting equipment can be exported to regions with strong demand for sustainable agriculture, such as Europe, North America, and the Middle East.

The rice straw compost fertilizer line is not just a production solution—it is a bridge between sustainable waste management and profitable agribusiness. By recycling rice straw into organic fertilizer, it helps farmers reduce pollution, improve soil quality, and achieve higher crop yields in the long run.

With global emphasis on eco-friendly farming practices, this production line offers both economic advantages and environmental benefits. From improving resource utilization to creating new income streams, the rice straw compost fertilizer line stands as a smart investment for farmers, agricultural enterprises, and investors worldwide.

In the future, as sustainable agriculture becomes the mainstream, the demand for organic fertilizer production equipment will continue to rise. Choosing a rice straw compost fertilizer line today means taking a proactive step toward green farming, environmental protection, and long-term profitability.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520