Seaweed granular organic fertilizer is gaining global attention as farmers and growers search for nutrient-rich, eco-friendly solutions that improve both crop quality and soil health. Unlike synthetic fertilizers that typically focus only on macronutrients, seaweed granular organic fertilizer offers a complex mixture of minerals, trace elements, natural growth hormones, and organic matter in an easy-to-apply granular form. This makes seaweed granular organic fertilizer not just a fertilizer, but a comprehensive soil health enhancer.

What is Seaweed Granular Organic Fertilizer?

Seaweed granular organic fertilizer is made by processing freshly harvested seaweeds (such as kelp, sargassum or laminaria) into concentrated granules. These granules are rich in bioactive compounds such as alginic acid, mannitol and cytokinin, which can promote root growth, enhance stress resistance and stimulate soil microbial activity.

The raw seaweed is processed into granular form, making the fertilizer more stable and easier to store. This is more convenient for both large-scale farms and small-scale growers. These granules can be spread by hand, applied with a fertilizer spreader, or integrated into an automated fertilization system.

Why Farmers are Choosing Seaweed Granular Organic Fertilizer Over Conventional Options

| Feature/Benefit | Seaweed Granular Organic Fertilizer | Conventional Chemical Fertilizer |

| Nutrient Source | Natural minerals, trace elements, plant hormones | NPK-focused, mostly synthetic compounds |

| Soil Health | Improves microbial balance, boosts organic matter | Can degrade soil structure over time |

| Environmental Impact | 100% biodegradable, ocean-sourced renewable resource | Potential chemical runoff and water pollution |

| Application Flexibility | Works for all crops, easy to blend with other organics | Mostly crop-specific formulas |

| Long-term Yield Stability | Builds soil fertility for years | Requires frequent reapplication for results |

Seaweed granular organic fertilizer stands out for its ability to provide both immediate nutrient benefits and long-term soil improvement, making it a sustainable investment for growers.

How Seaweed Granular Organic Fertilizer Works in the Soil

Seaweed granular organic fertilizer is not only a source of nutrients, but also a multifunctional soil conditioner that can directly deliver macronutrients, micronutrients, natural growth stimulants and bio-compounds to the root zone. After application to farmland, these granules gradually dissolve and release nitrogen, potassium, magnesium, calcium and trace elements over time, ensuring a continuous supply of nutrients to plants throughout their growth cycle.

Unique compounds in seaweed, such as alginate, mannitol, betaine and natural plant hormones (auxin, cytokinin, gibberellin), help improve plant metabolism, increase chlorophyll production, and enhance tolerance to drought, salinity and extreme temperatures. This means that crops can better cope with environmental challenges while maintaining high yields.

Moreover, its granular form makes it easy to store, transport and apply. Compared with natural seaweed or liquid preparations, farmers can spread it mechanically or by hand, with less dust and waste. As the granules decompose, they can also improve soil structure by increasing water retention, enhancing microbial activity and promoting aeration. In the long run, this can lead to healthier root systems and more fertile farmland.

How It’s Made: From Ocean Harvest to Farm Granules

Producing high-quality seaweed granular organic fertilizer is a carefully engineered process that transforms freshly harvested marine biomass into stable, nutrient-rich granules ready for agricultural use. The production typically follows these stages:

Step 1: Raw Seaweed Harvesting & Preprocessing

Fresh seaweed is collected from clean ocean waters and washed to remove excess salt, sand, and debris. This ensures that the final product is free from impurities and safe for crops.

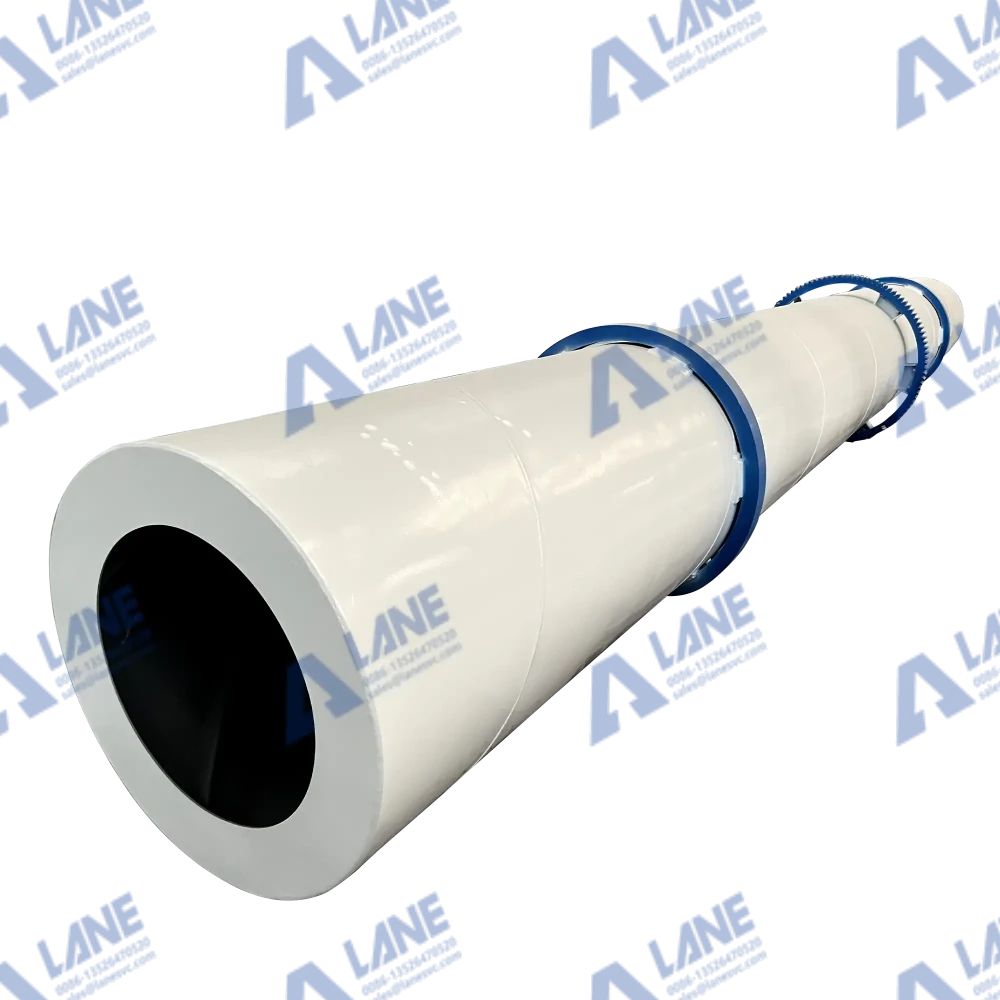

Step 2: Drying with a Rotary Drum Dryer

The cleaned seaweed is fed into a rotary drum dryer, which reduces moisture content to an optimal level for storage and further processing. This drying step locks in nutrients while preventing microbial spoilage.

Step 3: Grinding & Mixing

Once dried, the seaweed passes through a grinding machine to achieve a fine particle size. It is then blended in a horizontal mixer with other organic materials or nutrient additives (such as compost, poultry manure powder, or mineral supplements) to create a balanced fertilizer formula tailored to crop needs.

Step 4: Granulation&Polishing

The mixed material enters the granulation stage, where it can be shaped using either a double roller granulator for dense, oval granules or a stirring pin granulator for more porous, spherical granules. This step ensures uniform particle size for consistent application rates. The freshly formed granules are refined in a polishing machine, giving them a smooth, rounded surface that reduces dust, improves handling, and enhances their visual appeal for commercial markets.

Step 5: Screening with a Rotary Screening Machine

Granules pass through a rotary screening machine to separate oversized or undersized particles, ensuring that only standard-size fertilizer granules proceed to packaging. Any off-size material is recycled back into the production line.

Step 6: Final Packaging

Standard granules are sent to a packaging machine, where they are bagged into 25 kg, 50 kg, or bulk sacks. Packaging is designed for easy transportation, storage, and resale.

This combination of precision equipment and optimized production techniques ensures that LANE’s seaweed granular organic fertilizer meets the highest quality standards, delivering maximum benefits to farmers while retaining the natural advantages of seaweed.

Application Methods and Best Practices

Applying seaweed granular organic fertilizer correctly is essential to maximize its nutrient release and soil-conditioning benefits. Because the product is slow-releasing and rich in trace minerals, it can be applied at different stages of crop growth without risking nutrient burn.

(1)Pre-Planting Soil Preparation

Incorporate seaweed granular organic fertilizer into the soil 1–2 weeks before planting. A common application rate is 500–1,000 kg per hectare, depending on the crop and soil condition. Even distribution ensures that the granules break down gradually, feeding the soil microbiome before seedlings establish their roots.

(2) Side-Dressing During Growth

For crops like vegetables, strawberries, and maize, apply seaweed granular organic fertilizer along the planting rows midway through the growth cycle. This supports flowering and fruit development while maintaining healthy foliage.

(3) Turf and Lawn Care

Golf courses and landscaped lawns benefit from seaweed granular organic fertilizer because it strengthens grass root systems and enhances drought resistance. For turf, apply 20–30 g per square meter every 6–8 weeks during the growing season.

(4) Integration with Other Inputs

Farmers often combine seaweed granular organic fertilizer with compost or animal manure to create a more complete nutrient profile. When blended with nitrogen-rich sources, seaweed granules provide essential potassium and micronutrients, leading to balanced plant nutrition.

Best Practice Tip: Water the area immediately after applying the granules to activate microbial activity and speed up nutrient release. For drip irrigation systems, placing granules near the root zone ensures optimal uptake.

Case Study: Boosting Strawberry Yield in Coastal Farms

A strawberry farm in the coastal area of Southeast Asia is facing challenges such as poor sandy soil, rapid drainage, and the need for frequent fertilization. Although traditional chemical fertilizers can bring short-term effects, they can lead to the accumulation of soil salts and reduce the sweetness of strawberries. The farm switched to the LANE high-end product series of seaweed granule organic fertilizer. They adopted a seasonal fertilization plan:

Before planting: Use a rototiller to apply 800 kilograms of fertilizer per hectare to the surface soil.

Mid-season top-dressing: Apply 300 kilograms of fertilizer per hectare in the row between flowering.

Supplementary fertilization: Apply an additional 200 kilograms of fertilizer per hectare after harvest to restore soil health.

One year later:

Increased yield: The average yield of strawberries increased by 18%, and the fruit size was larger.

Improved quality: The Brix (sugar content) increased by 12%, enhancing sweetness and market value.

Soil health: The organic matter content increased from 1.8% to 2.7%, and the water retention ability improved.

Farmer feedback

The farm manager pointed out that the seaweed granule organic fertilizer can gradually release nutrients, reducing the need for frequent fertilization, lowering overall labor costs, and improving sustainability. The product also enabled them to promote strawberries under the slogan of “organic marine mineral cultivation”, thus attracting high-end buyers.

The Growing Global Market for Seaweed Granular Organic Fertilizer

The demand for seaweed granular organic fertilizer is expanding rapidly worldwide, driven by both environmental regulations and consumer preferences for sustainably produced food. According to the latest agricultural market report, the global seaweed fertilizer market is expected to grow at a rate of 8-10% per year and reach a valuation of several billion dollars within the next decade.

The key factors driving this growth are as follows:

(1) Transition to organic agriculture

Governments in Europe, North America, and parts of Asia are providing incentives for organic agriculture, which aligns perfectly with the use of seaweed-based organic fertilizers. Seaweed-based products are favored due to their natural origin, low carbon footprint, and ability to enhance soil biodiversity.

(2) Climate resilience of agriculture

Seaweed fertilizers can improve the drought resistance, salt tolerance, and disease resistance of crops. As climate change has intensified the unpredictability of weather conditions, these advantages make seaweed-based fertilizers more attractive to farmers in coastal and arid regions.

(3) Expansion of applications beyond food crops

Although fruit, vegetable, and grain growers remain the main users of seaweed granular organic fertilizers, seaweed granular organic fertilizers are also becoming increasingly popular in lawn management, horticulture, and forestry. Their potassium-rich nature can promote vigorous flowering in ornamental plants and accelerate the early growth of seedlings.

(4) Emerging markets in coastal economies

Countries with abundant seaweed resources (such as Indonesia, the Philippines, Chile, and Norway) are investing in the construction of processing facilities to convert raw seaweed into high-value granular organic fertilizers for domestic use and export. This global trend means that companies entering the seaweed fertilizer industry today have the opportunity to expand both domestic and international markets with sustainable and highly profitable products.

Why Partner with LANE for Your Seaweed Fertilizer Project

Choosing the right partner is critical when launching or expanding a seaweed granular organic fertilizer business. LANE offers:

Complete Turnkey Solutions – From raw seaweed processing to final granule packaging, including rotary drum dryers, grinding machines, double roller granulators, polishing machines, and drum screening equipment.

Custom Plant Design – Tailored layouts to meet your target capacity, raw material type, and market requirements.

Proven Experience – Decades of expertise in fertilizer machinery manufacturing, with successful installations in over 30 countries.

After-Sales Support – On-site installation guidance, operator training, and spare parts supply.

With LANE, you gain not only reliable equipment but also the technical know-how to achieve efficient production and high-quality output.

Seaweed granule organic fertilizer offers powerful nutritional components, bioactive compounds and soil improvement properties. Whether you are a small-scale farmer dedicated to improving crop health, or an investor seeking to enter the booming organic fertilizer market, algae granule fertilizer can provide you with sustainable profit opportunities.

With the right production technology and market strategy, such as those provided by LANE, seaweed fertilizer projects can deliver exceptional returns while supporting healthier soils and cleaner farming practices.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520