In today’s eco-conscious world, small scale compost production line systems are gaining popularity.For farmers, community organizations, and sustainability-focused entrepreneurs, establishing a small scale compost production line presents an excellent opportunity to transform organic waste into valuable fertilizer while contributing to environmental conservation.These compact composting solutions are perfect for those who want to recycle organic waste efficiently without the need for a large investment or extensive land area.

1.Understanding Small Scale Compost Production Line

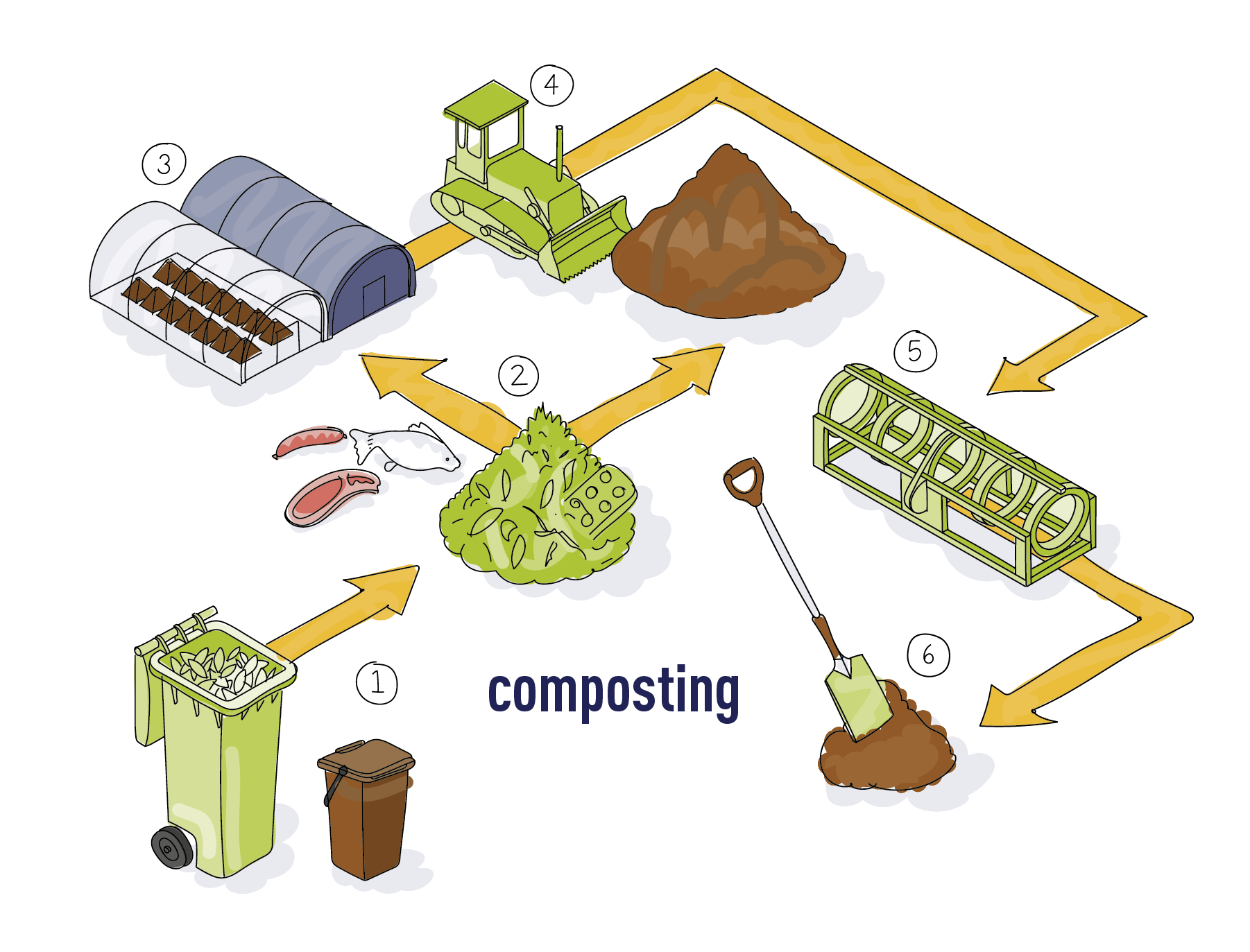

A small scale compost production line is a complete set of equipment used to turn organic waste—such as animal manure, crop residues, kitchen scraps, and garden waste—into nutrient-rich compost. Unlike large-scale industrial lines, these systems are designed for smaller capacities, typically ranging from 500 kg to 10 tons per day.

Despite their compact size, these production lines can include several essential machines, such as:

Crushing machines

Mixing equipment

Screening machines

Automatic bagging systems

These components work together to create a streamlined process that ensures efficient composting and high-quality output.

2.Key Advantages of Small Scale Compost Production Line

The decision to implement a small scale compost production line comes with numerous benefits that extend beyond simple waste management.

Environmentally, these systems significantly reduce methane emissions from decomposing organic matter while creating nutrient-rich soil amendments.

Economically, they offer farmers a way to cut fertilizer costs and potentially generate additional income through compost sales.

Operationally, small scale systems provide flexibility – they can be easily scaled up as demand grows and adjusted to process different types of organic materials throughout the seasons.

3.Applications of Small Scale Compost Production Lines

Small Farms: Manage livestock manure and crop waste efficiently.

Greenhouses: Convert plant residues into compost to improve soil fertility.

Municipal Projects: Use in community composting programs.

Food Processing Units: Recycle food scraps and organic by-products.

These diverse applications make small scale compost production lines a practical investment for anyone dealing with organic material on a small or medium scale.

4.Essential Components for Effective Operation

A well-designed small scale compost production line requires careful integration of several key components to ensure efficient processing and high-quality output. Each element plays a distinct role in transforming raw organic materials into premium compost, with specific equipment choices depending on the types of materials being processed and the desired final product characteristics.

(1) Pre-Processing Equipment: The Foundation of Quality Compost

The journey begins with proper material preparation. A robust shredding system serves as the workhorse of the small scale compost production line, reducing bulky organic matter into uniform particles that decompose faster and more evenly. For operations handling diverse materials, double shaft mixers offer versatility in processing everything from tough crop residues to food waste.

(2) Composting Reactors: The Heart of the System

The core of any small scale compost production line is its composting unit.It accelerates aerobic fermentation by turning and mixing the compost pile, ensuring proper oxygen supply.

(3) Crushing process: A Key Step in the Pre-treatment of Organic Materials

In a small scale composting production line, the grinding process is an important pre-treatment step for ensuring efficient composting. This stage converts various organic raw materials into uniform particles suitable for composting, creating ideal conditions for the subsequent fermentation process.

(4) Post-Processing and Refinement

After active composting, the small scale compost production line shifts to product refinement:

Screening Equipment: Rotary trommels with interchangeable mesh sizes separate finished compost from larger particles that may need further decomposition. Vibratory screens offer higher precision for specialty products.

Curing Area: Often overlooked but critical, a designated curing space allows compost to stabilize and develop beneficial microbial populations. This can be simple covered bays or more sophisticated aerated storage.

(5) Material Handling Systems

Efficient movement of materials between stages is crucial:

Conveyors: Belt or chain systems for continuous operations

Bucket Loaders: For batch systems with adequate space

Specialized Transfer Carts: For very small operations

The most effective systems carefully match component selection to the specific organic waste streams being processed, available resources, and intended compost markets. A well-balanced small scale compost production line optimizes the biological process while minimizing labor and energy inputs, creating a sustainable operation that produces consistent, high-value compost products.

A small scale compost production line is not just a machine—it’s a step toward sustainable and profitable agriculture. Whether you’re a smallholder farmer, a startup in organic fertilizer production, or a local recycling initiative, this compact solution can help you turn waste into wealth.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520