Brazil is a global powerhouse for agriculture, particularly in soybean production. However, with massive harvests comes a massive amount of leftover waste. We recently helped a partner in Brazil turn this challenge into a goldmine by installing a professional soybean residue organic fertilizer production line with a 5t/h capacity. This project shows how “waste” can be transformed into high-quality plant food that heals the soil.

In recent years, the world has shifted its focus toward sustainable farming. Brazil, with its vast stretches of farmland, is at the forefront of this movement. Farmers are looking for ways to reduce their reliance on expensive chemical fertilizers. This is where soybean residue organic fertilizer production becomes a game-changer.

Soybean residue, including the husks, stalks, and the meal left over after oil extraction, is rich in organic matter. When processed correctly, it doesn’t just feed the plant; it restores the biology of the soil. Our mission is to provide the technology that makes this transition easy and profitable for factory owners and farmers alike.

If you are in the farming business, you know that soybean husks and stalks are packed with nutrients. Instead of letting these residues rot in the field or burning them—which creates environmental hazards—a soybean residue organic fertilizer production system allows you to recycle nitrogen, phosphorus, and potassium back into the earth.

The organic matter in soybean waste improves soil structure, helps the ground hold more water, and encourages beneficial microbes to grow. It’s eco-friendly, and more importantly, in today’s market, it’s highly profitable. A well-run soybean residue organic fertilizer production facility can turn a “waste problem” into a “premium product” in just a few weeks.

Building a 5t/h production line requires more than just a pile of waste; it requires a synchronized dance of specialized machinery. Here is the equipment we integrated into the Brazil project and how each machine plays a vital role in the soybean residue organic fertilizer production process.

Soybean stalks can be tough and long. To start the process, the material needs to be broken down into a consistent size. We use high-efficiency crushers that shred the residue into fine particles. This increases the surface area for bacteria to work on during the fermentation stage, which is the “secret sauce” of any soybean residue organic fertilizer production line.

Before the residue becomes fertilizer, it must ferment. We supplied a crawler-type compost turner that moves through the raw material piles.

Oxygenation: It turns the piles to introduce fresh air.

Temperature Control: It helps release excess heat so the beneficial bacteria don’t “cook” themselves.

Moisture Management: It ensures the moisture is even throughout the pile. Without proper fermentation, you don’t have fertilizer; you just have wet beans. This stage is where the raw soybean residue organic fertilizer production material truly transforms.

Sometimes, soybean residue is mixed with other organic materials like chicken manure or sugar cane bagasse to create a “balanced diet” for crops. Our horizontal mixers ensure that every handful of the final product has the exact same nutrient profile. Precision in the soybean residue organic fertilizer production process is what separates professional-grade fertilizer from amateur compost.

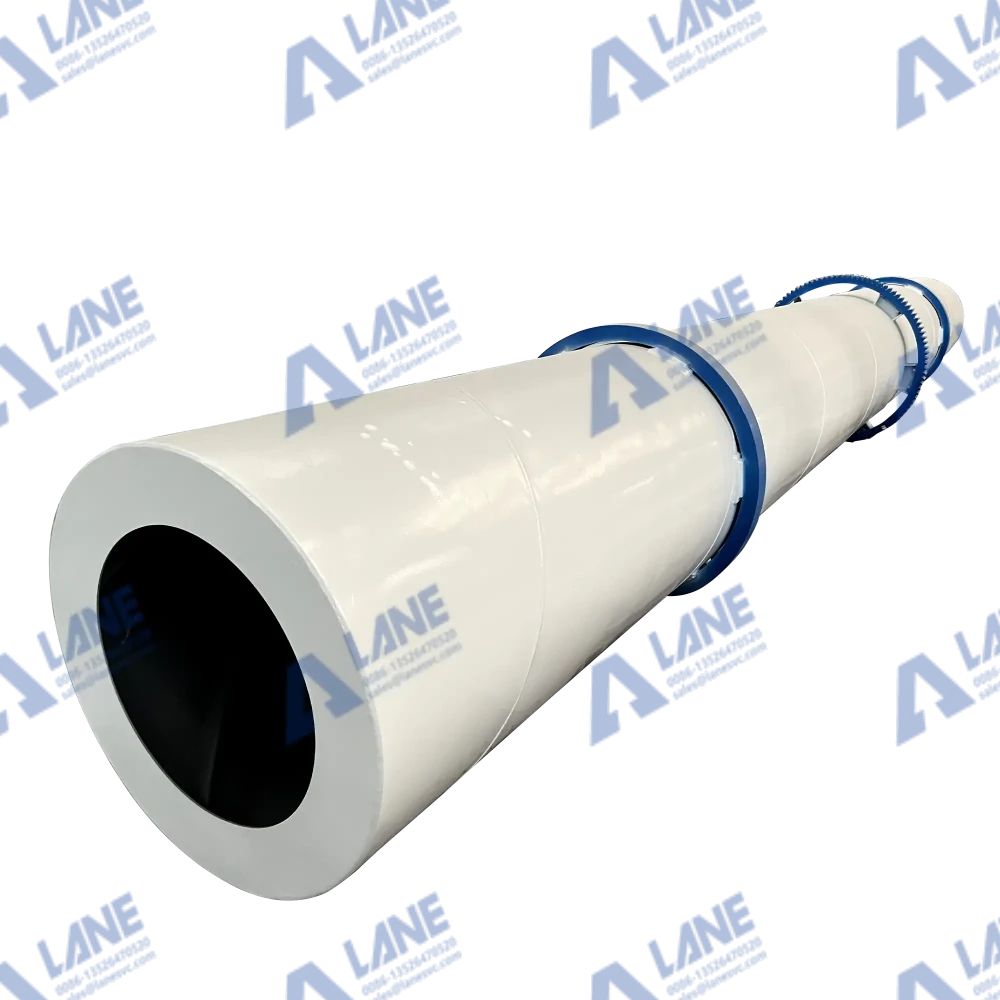

This is where the magic happens. After fermentation, the material is a bit messy and powdery. Our stirring pin granulator turns that loose compost into neat, round pellets. For this soybean residue organic fertilizer production line in Brazil, we chose a specialized granulator that handles organic fibers perfectly. Unlike chemical fertilizers, organic materials can be sticky or fibrous. Our machine uses high-speed centrifugal force to create uniform pellets that are easy for farmers to spread using standard equipment.

Fresh pellets are warm and moist—not ideal for bagging. If you bag them wet, they will grow mold. We installed a large rotary dryer to whisk away moisture using controlled heat, followed by a cooling machine. This duo ensures the pellets are hard, dry, and shelf-stable. In a large-scale soybean residue organic fertilizer production setup, the cooling stage is vital for maintaining the integrity of the pellet during long-distance shipping across Brazil.

Consistency is key to a premium brand. The rotary screening machine acts as a filter. It vibrates at high speeds to separate the pellets by size.

Fine Dust: Goes back to the granulator.

Over-sized Lumps: Go back to the crusher.

Perfect Pellets: Move forward to the packaging line. This ensures that every bag of soybean residue organic fertilizer production output looks professional and high-end, matching the quality of any commercial chemical fertilizer.

To give the fertilizer a professional “shine” and prevent the pellets from sticking together in humid climates, we often add a coating machine. This adds a thin layer of protective oil or nutrients to the outside of the pellet. It’s an extra step that makes a huge difference in the marketability of the soybean residue organic fertilizer production results.

Finally, the pellets are weighed and sealed into bags ranging from 25kg to 50kg, or even “big bags” of 1 ton. Our automatic system handles the 5-ton-per-hour flow without breaking a sweat, reducing labor costs and ensuring every customer gets exactly what they paid for.

Building a soybean residue organic fertilizer production line is a big investment. You need a partner who knows the “nuts and bolts” of the industry. Here is why clients choose us:

20+ Years of Professional Experience: We have been focused on fertilizer machinery manufacturing in China for over two decades. We’ve seen the evolution of the industry and have helped hundreds of clients build successful businesses.

Custom Engineering & Installation: Our engineering team doesn’t do “one size fits all.” For the Brazil project, we designed the layout to fit the client’s specific factory dimensions. We don’t just ship boxes; we design systems.

One-Stop Service: We provide a full-scale service. This means we help with the initial design, manufacture the equipment, send engineers for installation, and provide lifelong after-sales support. Whether it’s troubleshooting or a future upgrade, we stay with you.

International Standards: Quality is our priority. Our products comply with ISO9001 and CE international quality standards. When you run a soybean residue organic fertilizer production line using our machines, you are using world-class technology.

Diverse Product Range: While we love organic fertilizer, we are also experts in compound fertilizer and liquid fertilizer machinery. We have the tools to help your business grow in any direction.

By setting up a soybean residue organic fertilizer production line locally, Brazilian entrepreneurs are saving a fortune on logistics. Instead of shipping waste away and buying fertilizer back, they are closing the loop right on their own doorstep. This “circular economy” model is the future of agriculture.

The 5t/h capacity is particularly popular because it is the “sweet spot”—large enough to handle the waste of a massive farm or collective, but manageable enough to run with a localized team.

The success of the 5t/h soybean residue organic fertilizer production line in Brazil proves that sustainability and profit go hand in hand. With the right equipment—the turners, the granulators, and the dryers—what was once a disposal headache becomes a high-value asset.

We are proud to be the technical backbone for these projects. Our company isn’t just selling metal; we are selling a solution for a greener planet and a more profitable farm.

Are you ready to turn your agricultural waste into a brand-new revenue stream? Whether you have soybean residue, animal manure, or food waste, we can help you build the perfect system.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520