In today’s eco-conscious farming landscape, the spherical granule organic fertilizer granulator stands out as a game-changer for producers aiming to create premium, round-shaped organic fertilizers. These machines transform fermented organic materials—like livestock manure, crop residues, and bio-waste—into uniform, ball-like granules that are easy to handle, store, and apply. Why the hype around spherical shapes? Round granules dissolve slowly, release nutrients steadily, and minimize waste, making them a favorite among farmers seeking sustainable solutions. The spherical granule organic fertilizer granulator not only enhances product appeal but also improves market value, turning simple organic matter into profitable, high-demand fertilizer. Many farmers say these round pellets make their work easier and help crops grow better with less effort.

Producing perfect spherical granules often involves a combination of specialized equipment. Among the most popular are the stirring pin granulator, disc granulator, and polishing machine (also known as the throwing or rounding machine). Each plays a unique role in the granulation process, addressing common concerns like granule uniformity, strength, production efficiency, and energy consumption. These machines work well together to make high-quality products. Let’s dive into these three machines and see how they contribute to creating top-tier spherical granule organic fertilizer granulator outputs. You will find they are practical and helpful for everyday use.

The stirring pin granulator is a powerhouse for wet granulation, ideal for high-moisture organic materials. It works by using high-speed rotating pin to stir and form fine powders into dense, spherical particles. Customers often worry about handling wet, sticky manure-based feeds—this machine excels here, processing materials with 20-40% moisture without pre-drying. Granulation rates soar above 90%, with particle sizes adjustable from 0.3-5mm by tweaking rotor speed. Lower speeds yield larger granules, higher speeds smaller ones. Its advantages? High efficiency for large-scale production, even particle sizes, and low dust since spheres have no sharp edges. Energy savings are big—no need for much drying afterward. The machine is tough and lasts long, even with tough materials like straw. For producers who want consistent results, the stirring pin granulator in a spherical granule organic fertilizer granulator setup gives strong pellets that stay good during shipping and use.

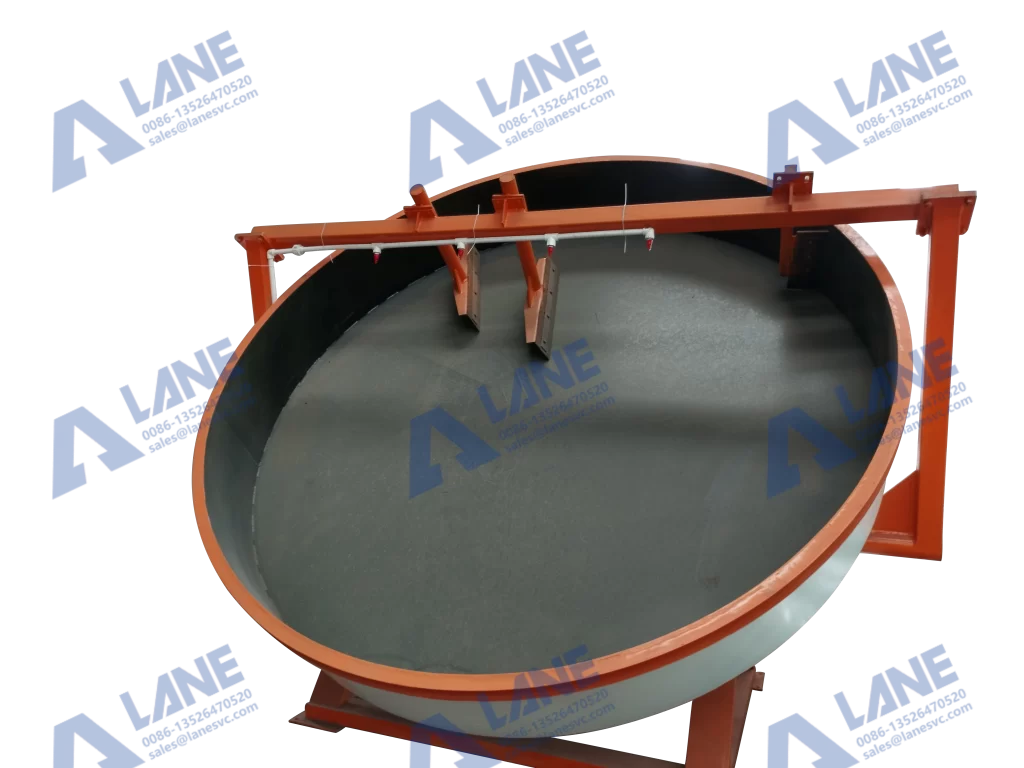

Shifting to the disc granulator, this classic machine offers simplicity and versatility, perfect for small to medium operations. It has a tilted rotating disc where powdered material gets sprayed with water and rolls into balls under force and gravity. Granulation rates hit 93-95%, and you can easily change particle size by adjusting the disc. Operators like its low energy use and easy care—no complicated parts. It works with many kinds of organics, like chicken manure or sludge, and makes fairly round granules. Worried about cost or ease? This machine is cheap to buy, starts smoothly, and runs steadily. It has several outlets so you can work without stopping often, saving time and work. Though granules might need extra polishing for perfect shape, it’s a great start for spherical granule organic fertilizer granulator production at a good price.

For that final touch of perfection, enter the polishing machine, often called the throwing rounder. This is the secret weapon for achieving truly beautiful, market-ready spheres. It takes pre-formed granules and tumbles them in rotating cylinders. Force and rolling smooth the edges and make them stronger and rounder. Rates reach 95-98%, with even sizes, shiny looks, and less waste. It keeps moisture low for easier drying and uses less power. Farmers who care about looks and sales love it—rough pellets turn into perfect balls that spread easily and break less. With multiple stages, it handles a lot at once. In a full spherical granule organic fertilizer granulator line, this machine turns good granules into great ones that sell for more.

At LANE, as a leading manufacturer of fertilizer machinery in China with over 20 years of experience, we specialize in delivering tailored solutions. Our professional engineering team designs and manufactures complete production lines, including these advanced granulators, customized to your specific needs. We follow ISO 9001 and CE standards for reliable quality. From installation to ongoing support, maintenance, and upgrades, LANE ensures your spherical granule organic fertilizer granulator line runs smoothly and efficiently every day.

Why choose a spherical granule organic fertilizer granulator approach? Round pellets prevent caking, spread nutrients evenly, and suit modern farming tools. Compared to other shapes or powders, they last longer in storage and work better in fields, helping plants grow stronger. Stirring pin models handle big jobs with tough feeds; discs are easy on the budget; polishers make everything look perfect. Together, they make spherical granule organic fertilizer granulator production simple and effective. Many users find their farms more productive and profitable with these round fertilizers.

Investing in these machines means higher returns—sell premium round organic fertilizer that stands out in the market. With LANE’s expertise in organic, NPK, and compound lines, we help you build a future-proof operation that grows with you. The spherical granule organic fertilizer granulator revolution is here, blending innovation with sustainability. Whether you are scaling up or starting fresh, these granulators deliver results that excite producers and please the planet. It’s a smart choice for better farming and a greener world.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520