Across the Philippines, more farms and small businesses are looking for better ways to use the large amount of straw left after every harvest. Instead of burning it or leaving it unused, many people are discovering a new idea that is both practical and profitable: using a Straw Pellet Production Line in the Philippines to turn straw into small, solid fuel pellets. These pellets are easy to store, easy to transport, and useful for heating, cooking, and even exporting to other countries that need biomass fuel.

One reason this idea is growing so quickly is that the Philippines produces a huge amount of rice straw and corn stalks every year. In many places, this material piles up with no clear purpose. But today, with rising energy prices and more awareness of environmental issues, straw is no longer seen as trash. With the right machines working together, it can become a valuable product.

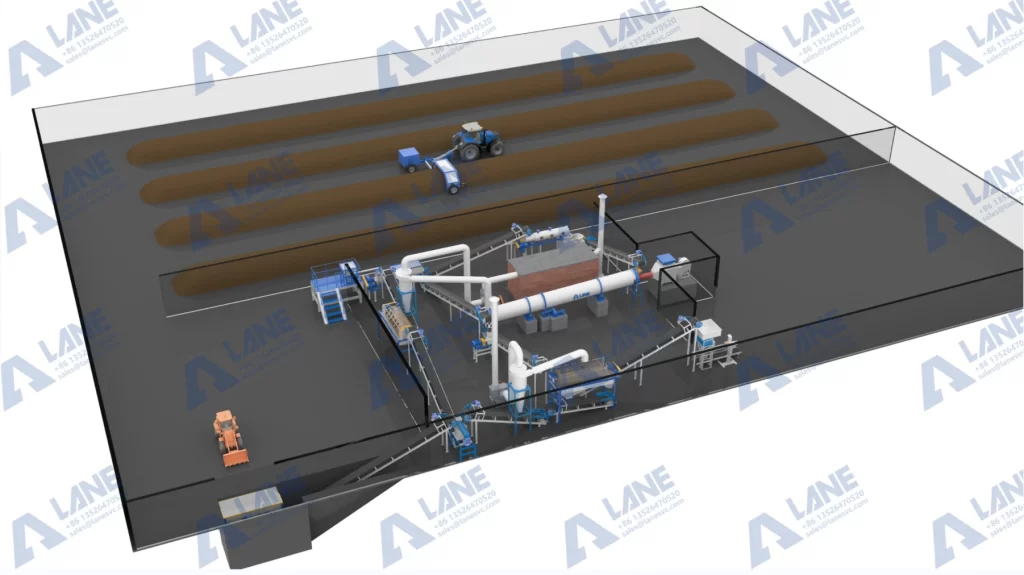

The production line itself is not difficult to understand. It is simply a set of machines that take raw straw and turn it step by step into clean, firm pellets. To help new investors and farmers understand the process, this article explains each machine in simple terms and shows how a complete Straw Pellet Production Line in the Philippines works from start to finish.

The first machine in the line is the dynamic batching machine. Its job is simple: it feeds straw into the system evenly. Instead of throwing in a big pile at once, the batching scale helps the line receive the right amount of material at the right speed.

This matters because steady feeding means:

In the Philippines, where straw varies from province to province, this machine helps make the Straw Pellet Production Line in the Philippines more consistent and easier to manage.

Straw often comes in long, messy pieces. This makes it hard for later machines to handle. The vertical crusher solves this problem by chopping the straw into smaller, more manageable pieces.

A good crusher:

Rice straw in the Philippines is often tough and contains silica, so the crusher is especially important in a Straw Pellet Production Line in the Philippines. Without it, the rest of the line would struggle.

This is the heart of the whole production line. The vertical ring die granulator presses the processed straw into small, tight cylinders called pellets. The machine uses pressure and heat to shape the material.

Why this machine is important:

When this part works well, the Straw Pellet Production Line in the Philippines can create strong pellets that burn well and are easy to sell.

Straw in the Philippines is usually quite wet, especially during the rainy season. Wet straw cannot be made into good pellets, so the dryer helps remove the extra moisture before pelletizing.

A good dryer:

Drying is a key step in every Straw Pellet Production Line in the Philippines, because the tropical climate makes raw straw naturally more humid.

When pellets come out of the pellet mill, they are very hot and soft. They need time to cool down and harden, and that is the job of the cooler.

The cooler:

With proper cooling, the Straw Pellet Production Line in the Philippines can produce pellets that stay strong during transport and do not crumble easily.

Not every pellet comes out perfect. Some break, and some turn to powder. The rotary screener separates good pellets from unwanted pieces.

This simple step:

Screening is important for building a good reputation, especially if the Straw Pellet Production Line in the Philippines plans to sell pellets to factories or export markets.

The last machine in the line is the packing machine. It fills bags with pellets and makes them ready for transport or storage.

It helps by:

Most Straw Pellet Production Line in the Philippines operations use 15 kg, 25 kg, 40 kg, or 1-ton bags depending on the market.

When all these machines work together, they turn straw into a clean, useful fuel. This helps farmers earn extra income, reduces waste, and offers a new source of energy for homes and small businesses. With steady demand from both local buyers and international markets, a complete Straw Pellet Production Line in the Philippines can create long-term benefits for many communities.

At LANE, we have been focusing on building and designing machinery for more than 20 years. Although we are known for fertilizer equipment, our engineering experience allows us to help customers build complete pellet production lines as well. For anyone planning a Straw Pellet Production Line in the Philippines, we provide full support—from choosing the right machines to installing them and guiding your team on how to use them.

We design systems based on your needs, your raw materials, and your production goals. We follow international quality standards like ISO 9001 and CE to ensure stable and reliable equipment. More importantly, we stay with our customers even after installation by offering maintenance, troubleshooting, and upgrades whenever needed.

Thanks to our background in organic fertilizer machines, NPK production lines, and compound fertilizer systems, we understand how to build equipment that works smoothly for many years. This experience helps us support pellet projects with the same level of care and reliability.

As renewable energy becomes more important and the agriculture sector continues to grow, the Straw Pellet Production Line in the Philippines is set to become an important industry. With simple, easy-to-understand machines and strong engineering support, turning straw into pellets is becoming a practical solution that helps farmers, businesses, and the environment all at once.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520