Decades of chemical fertilizer use have destroyed the biodiversity of agricultural land and created environmental hazards. Farmers, distributors, and consumers are now demanding fertilizers that support long-term soil health and environmental resilience. This has created a booming market for sustainable agricultural fertilizers. Data shows that over 33% of global soil is degraded due to excessive chemical fertilizer use. Sustainable agricultural fertilizers have become the core driver of transitioning this land back to farmable land. This is a huge commercial opportunity for entrepreneurs who want to get into the fertilizer market.

The key to this opportunity is building a cost-effective, efficient, and scalable production line which separates a niche operation from a profitable, market-leading enterprise. LANE Heavy Industry, a leader in fertilizer machinery, provides end-to-end solutions that balance environmental benefits and profitability.

Sustainable agricultural fertilizers encompass a range of products, including organic fertilizers, bio-fertilizers, enhanced-efficiency fertilizers, and mineral-based fertilizers produced with a low carbon footprint. Their profitability is driven by:

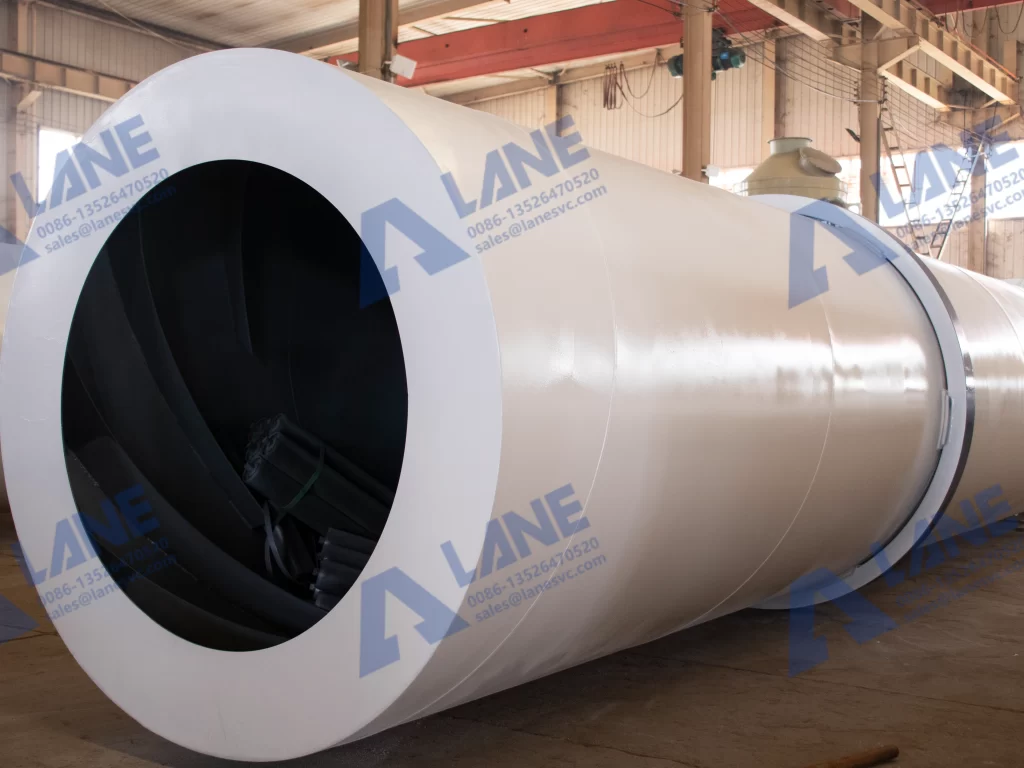

A durable and consistent production line must handle diverse, inconsistent raw materials and output a standardized, high-quality product. Here’s where LANE Heavy Industry’s engineered solutions come into play:

Profitability is eroded by downtime, high energy consumption, and inconsistent output. LANE Heavy Industry machinery is built to combat these challenges:

Investing in a LANE production line for sustainable agricultural fertilizers is a capital investment. A simplified ROI analysis should consider initial machinery investment and profits, especially when producing high-quality sustainable agricultural fertilizers that can command premium market prices.

Key Profit Drivers:

| Factor | Impact on Profitability | LANE Machinery Contribution |

| Raw Material Cost | Major driver; use of waste streams boosts margin. | Handles variable, challenging inputs reliably. |

| Production Uptime | Directly correlates to output volume and revenue. | Robust design minimizes unplanned downtime. |

| Energy Efficiency | Reduces ongoing operational expenditure (OPEX). | Optimized thermal systems and drive technology. |

| Product Consistency | Enables premium pricing and brand loyalty. | Precise process control and granulation technology. |

| Labor Requirements | Lower labor needs improve net margin. | High degree of automation from pre-processing to packing. |

From Production to Market: Ensuring Commercial Success

A great production line needs a market strategy. Consider:

Building a profitable production line for Sustainable Agricultural Fertilizers is response to global green policies as well as a strategic layout for long-term profitability. As the demand for Sustainable Agricultural Fertilizers surges, partnering with LANE is the key to seizing the 10-billion-dollar organic fertilizer market. LANE Heavy Industry’s machinery, with its efficient, flexible, and eco-friendly advantages, helps enterprises convert waste into wealth.

Q1: What types of Sustainable Agricultural Fertilizers can I produce with LANE machinery?

A: LANE’s flexible production lines can manufacture a wide variety of products, including Sustainable Agricultural Fertilizers such as organic granular fertilizer from compost, bio-organic fertilizer enriched with microbial agents, and compound fertilizers using sustainable mineral sources. The process can be tailored to your specific recipe.

Q2: How does the durability of LANE machinery handle corrosive organic materials?

A: LANE equipment is engineered for harsh environments. Key components in contact with material are often fabricated from or lined with stainless steel or special anti-corrosion alloys. This ensures a long service life and protects your investment, even when processing acidic or salty organic feedstocks. Using LANE machinery for Sustainable Agricultural Fertilizers guarantees reliable, long-term operation.

Q3: Can LANE help with the entire project, from design to installation?

A: Yes. LANE Heavy Industry offers turnkey solutions. Our service includes initial consultation and feedstock analysis, production line design, manufacturing, installation and commissioning, and comprehensive operator training. We provide end-to-end support to ensure your project’s success, especially when producing high-quality Sustainable Agricultural Fertilizers.

Q4: What is the typical payback period for an investment in such a production line?

A: The payback period varies based on scale, feedstock costs, local energy prices, and final product value. However, with efficient LANE machinery optimizing operational costs and enabling premium product pricing, many facilities see a return on investment within 2 to 4 years, depending on market conditions and operational efficiency.

Q5: How automated are these production lines? Can they be operated with a small crew?

A: LANE designs for optimal automation. A well-designed line can indeed be operated by a small crew, primarily responsible for monitoring, quality control, and maintenance. Automated control systems handle batching, granulation parameters, temperature control, and packaging, significantly reducing labor requirements and human error.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520