If you are planning to start a fertilizer production line or upgrade your current factory, you might find yourself staring at a catalog of machines wondering, “Which one do I actually need?” To make an informed choice, you must understand the difference between horizontal mixers and twin-shaft mixers. These two workhorses are the heart of the blending process, but they serve very different roles depending on your specific goals.

At LANE, we have spent over 20 years focusing on fertilizer machinery manufacturing in China. We have seen thousands of production lines, and we know that picking the wrong equipment can lead to uneven blending or wasted energy. In this article, we will break down the technical and practical details to help you find the perfect fit.

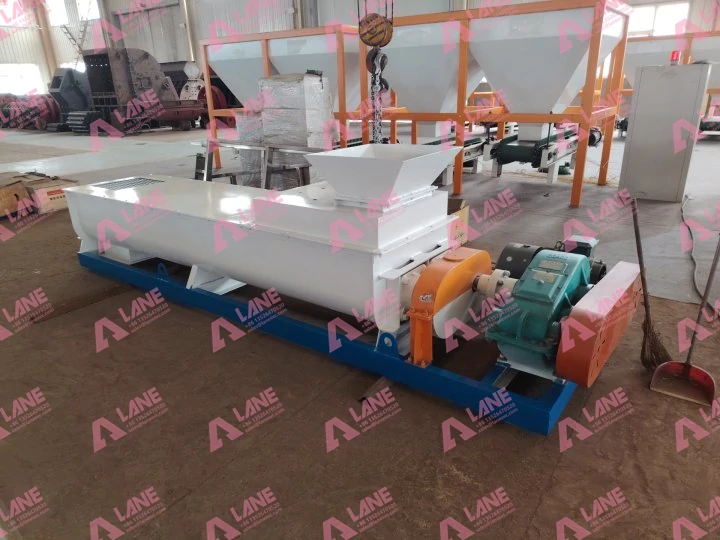

A horizontal mixer (often called a single-shaft mixer) consists of a U-shaped container and a single rotating shaft equipped with ribbons or paddles. It is a classic choice for many organic and compound fertilizer plants. The design is simple but very effective. As the shaft turns, the materials are moved from one end of the tank to the other, ensuring that every batch is consistent.

Because it uses a single shaft, this machine is often more compact and cost-effective. It is famous for its “gentle” mixing style. If your raw materials are fragile or if you are working with dry powders that need to be blended thoroughly without being crushed too hard, this is usually the go-to option. Our customers often choose this model when they are setting up a small to medium-sized organic fertilizer line because it is easy to maintain.

On the other hand, the twin-shaft mixer is like the high-powered cousin of the single-shaft version. Instead of one shaft, it has two horizontal shafts with overlapping paddles. These shafts rotate in opposite directions, creating a high-intensity mixing zone.

This counter-rotating action doesn’t just move the material; it throws it into a “weightless” state where the particles collide and blend rapidly. This results in a very fast mixing cycle. If you are dealing with heavy materials, wet slurries, or a production line that requires massive output every hour, this is the superior choice. This is one of the biggest points when discussing the difference between horizontal mixers and twin-shaft mixers: one is built for gentle consistency, while the other is built for industrial speed and power.

When we look closer at the difference between horizontal mixers and twin-shaft mixers, several key factors emerge that will impact your daily operations.

The most obvious difference between horizontal mixers and twin-shaft mixers is how fast they work. A single-shaft horizontal mixer takes more time to achieve a uniform blend because the material follows a simpler circular path. In contrast, the twin-shaft version uses turbulent flow to mix materials in nearly half the time. If your factory values high-speed throughput, the twin-shaft model is the clear winner.

Another major difference between horizontal mixers and twin-shaft mixers involves the type of fertilizer you are making. If you are blending dry, light organic compost, the horizontal mixer is perfect. However, if you are adding liquids or dealing with sticky compound materials, the dual shafts are much better at breaking up clumps and ensuring moisture is distributed evenly.

Simplicity is where the single-shaft model shines. When comparing the difference between horizontal mixers and twin-shaft mixers, the horizontal mixer is much easier to clean and repair because it has fewer moving parts. The twin-shaft mixer requires more attention to its synchronized gearbox and dual seals, making it a better fit for plants with a dedicated maintenance team.

Making these technical decisions can be stressful, but you don’t have to do it alone. We are more than just a manufacturer; we are your partners in production. With over two decades of experience, we have mastered the art of fertilizer machinery. We understand the difference between horizontal mixers and twin-shaft mixers better than anyone, and we use that knowledge to help you succeed.

Customized Engineering: We don’t believe in “one size fits all.” Our professional engineering team can design and manufacture equipment tailored to your specific factory layout. We can even install the entire production line for you from scratch.

One-Stop Service: From the first day of installation to long-term maintenance, we stay with you. We offer full after-sales support, troubleshooting, and even equipment upgrades to ensure your line never stops running.

International Quality: Our products are not just “good”—they are certified. We follow ISO9001 and CE international quality standards, so you can trust that every machine we ship is safe and durable.

Core Product Expertise: Whether you need a full NPK production line, organic fertilizer equipment, or specialized compound fertilizer machines, we provide the complete range with professional precision.

To further clarify the difference between horizontal mixers and twin-shaft mixers, let’s look at two common scenarios we see at LANE.

Scenario A: The Organic Fertilizer Startup

A client in Southeast Asia wanted to process 5 tons of chicken manure per hour. They needed a machine that was easy to use and wouldn’t break the bank. After explaining the difference between horizontal mixers and twin-shaft mixers, we recommended a horizontal mixer. It handled their dry compost perfectly and allowed them to start production with a lower initial investment.

Scenario B: The High-Volume NPK Plant

Another client needed to produce 20 tons per hour of compound fertilizer involving liquid additives. In this case, the difference between horizontal mixers and twin-shaft mixers was clear. They needed the power and speed of the twin-shaft model to prevent the material from clumping and to keep the production line moving at maximum capacity. We designed a custom twin-shaft system for them that met CE standards and has been running 24/7 ever since.

| Feature | Horizontal Mixer (Single-Shaft) | Twin-shaft Mixer |

| Mixing Action | Gentle, folding motion | High-energy, turbulent tossing |

| Output Speed | Standard | Very Fast |

| Best For | Dry powders, Organic compost | Wet materials, NPK, High-volume |

| Structure | Simple, easy to clean | Complex, high-efficiency |

| Footprint | Compact | Larger |

Understanding the difference between horizontal mixers and twin-shaft mixers is the key to a successful fertilizer business. One offers simplicity and gentle blending, while the other offers industrial power and rapid results.

By choosing LANE, you are choosing 20 years of Chinese manufacturing excellence. We provide the expertise, the customization, and the global standards (ISO9001/CE) that your business deserves. We can help you analyze your raw materials and production goals to determine exactly where the difference between horizontal mixers and twin-shaft mixers will impact your bottom line.

Let us take the guesswork out of your machinery needs. We specialize in providing NPK lines, organic fertilizer equipment, and specialized blending solutions that are built to last. The right equipment is waiting for you, and we are ready to help you install it and keep it running for years to come.

Understanding the difference between horizontal mixers and twin-shaft mixers today can save you thousands of dollars in energy and maintenance costs tomorrow. Trust the experts at LANE to guide you every step of the way.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520