Every year, the global coffee industry generates millions of tons of waste. The majority of it comes from industrial coffee grounds — the leftover residue from instant coffee and beverage manufacturing. Traditionally, this organic by-product has been discarded or incinerated, causing significant environmental concerns. However, with the rise of sustainable agriculture and circular economy practices, turning coffee grounds into fertilizer has become a practical and profitable solution.

This process not only addresses waste disposal challenges but also produces valuable organic fertilizers that enrich soil, support microbial life, and promote greener farming systems.

The Environmental Problem of Industrial Coffee Waste

Coffee production and processing industries produce enormous amounts of wet organic residue. On average, each ton of coffee beans processed generates around 650–700 kg of spent coffee grounds (SCG).

If untreated, these coffee grounds release methane and CO₂, contributing to greenhouse gas emissions. Their high organic load and acidity can also damage soil and water ecosystems when dumped directly into the environment.

By turning industrial coffee grounds into fertilizer, companies can significantly reduce waste pollution while creating a renewable nutrient source for crops and gardens.

Why Coffee Grounds Are Ideal for Fertilizer Production

Industrial coffee grounds are rich in organic matter, nitrogen, and essential micronutrients that support plant growth. When composted or processed correctly, they provide an excellent base for organic fertilizer formulations.

Main nutrient components of coffee grounds include:

Nitrogen (N): Promotes leaf and stem growth.

Phosphorus (P): Stimulates root development and flower formation.

Potassium (K): Enhances fruit quality and plant resistance.

Magnesium, Calcium, Iron, and other trace minerals that improve soil fertility.

Moreover, the fibrous texture of coffee grounds helps improve soil aeration and water retention, making them especially suitable for sandy or degraded soils.

The Process of Turning Coffee Grounds into Fertilizer

The conversion process from waste to fertilizer involves several key stages designed to stabilize and enrich the material. With modern composting and organic fertilizer equipment, this can be achieved efficiently and safely.

1. Raw Material Collection and Pre-Treatment

Industrial coffee grounds are collected from coffee factories or beverage processing plants. Excess moisture (often 60–70%) is reduced through mechanical dewatering or sun drying. This ensures better aeration and faster fermentation.

2. Composting and Fermentation

The pre-treated coffee grounds are mixed with carbon-rich materials such as straw, sawdust, or rice husk to balance the carbon-to-nitrogen ratio (C/N ≈ 25–30).

Using a crawler type compost turner or wheel type compost machine, the mixture is regularly turned to maintain proper oxygen levels and temperature (55–65°C).

Over 15–20 days, microorganisms break down the organic matter, transforming it into stable compost.

3. Crushing and Mixing

Once fermentation is complete, the composted material is crushed and blended with other organic nutrients — such as humic acid, amino acids, or trace minerals — to enhance fertilizer quality.

4. Granulation and Drying (Optional)

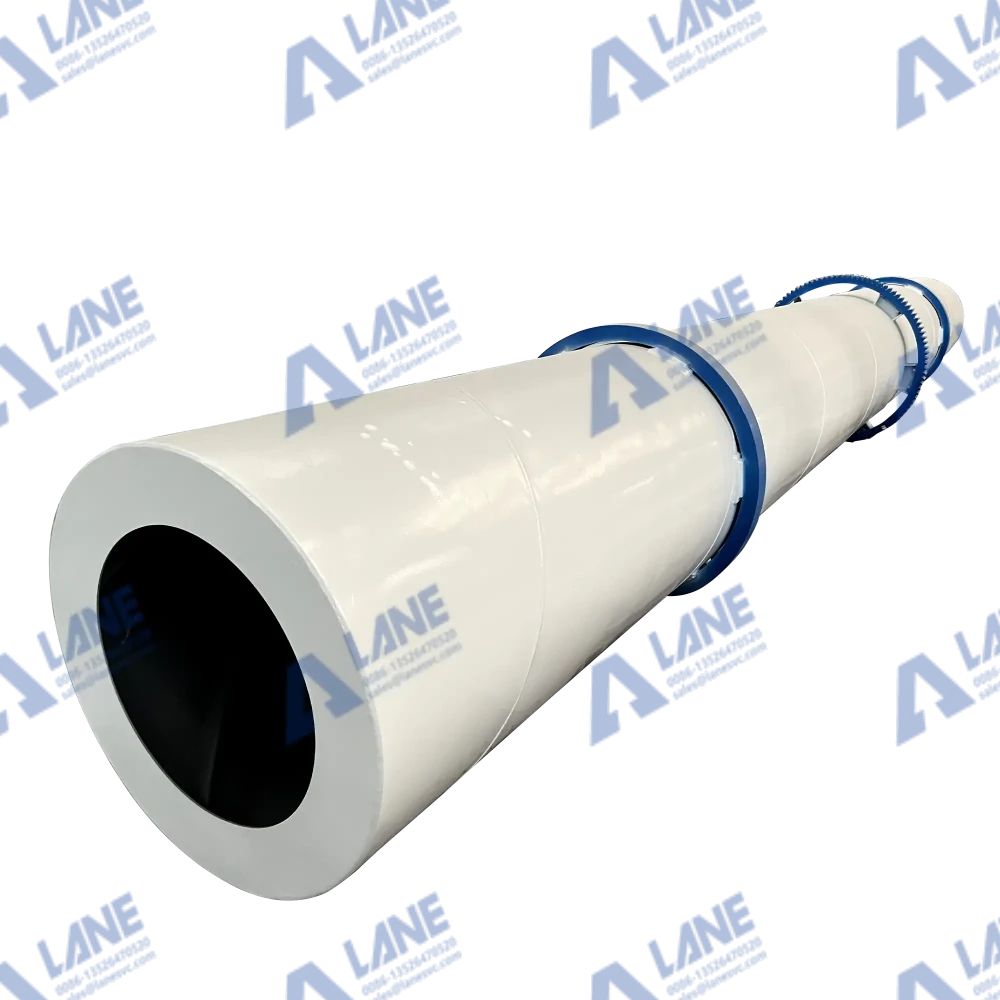

For commercial production, the compost can be processed using organic fertilizer granulating equipment (e.g., disc granulator, rotary drum granulator) to form uniform, easy-to-apply granules.

The granules are then dried and cooled to remove excess moisture.

5. Packaging and Storage

The final product — organic coffee-based fertilizer — is packaged into 25–50 kg bags or bulk containers for agricultural use.

LANE Heavy Industry provides a full set of equipment solutions for turning industrial coffee grounds into fertilizer, including compost turners, crushers, mixers, granulators, and automatic packaging systems.

Benefits of Coffee Ground-Based Organic Fertilizer

Transforming coffee grounds into organic fertilizer provides multiple environmental and agricultural benefits:

Waste Reduction: Diverts tons of industrial coffee waste from landfills.

Eco-Friendly Agriculture: Replaces chemical fertilizers with natural, biodegradable alternatives.

Improved Soil Health: Increases soil organic matter, porosity, and microbial activity.

Enhanced Crop Yield: Provides a slow-release source of nitrogen and other essential nutrients.

Economic Value: Converts low-cost waste into high-value fertilizer products for the agricultural market.

Additionally, coffee-ground fertilizers improve the flavor and color quality of crops such as vegetables, fruits, and ornamental plants — making them popular among organic farmers.

Market Potential and Industrial Opportunities

As global coffee consumption continues to rise, so does the volume of industrial coffee waste.

Countries like Brazil, Vietnam, Indonesia, and Ethiopia — leading coffee producers — generate enormous amounts of coffee grounds each year, offering huge potential for fertilizer conversion plants.

Governments and private enterprises are increasingly supporting projects that upcycle organic industrial waste into fertilizers or bioenergy.

The market for coffee-ground fertilizers is expanding rapidly, particularly within the organic farming and landscaping sectors.

By establishing an automated fertilizer production line for coffee grounds, companies can not only reduce waste management costs but also create sustainable revenue streams aligned with green economy goals.

Why Choose LANE Heavy Industry

Henan LANE Heavy Industry is a global supplier of organic fertilizer production equipment.

With years of engineering experience, LANE designs customized systems for turning industrial coffee grounds into fertilizer, covering every step from composting to granulation.

LANE’s advantages include:

Advanced composting technology with crawler and wheel type compost turners

Efficient mixing, crushing, and granulation systems for organic materials

Intelligent control systems ensuring stable operation and consistent quality

Professional project design and after-sales support for international clients

Our fertilizer production solutions have been successfully applied in Southeast Asia, Africa, and South America, helping clients transform organic waste into profitable agricultural resources.

Conclusion

Turning industrial coffee grounds into fertilizer represents a powerful example of circular economy innovation — transforming waste from one industry into a valuable input for another.

By integrating advanced composting technologies and automated fertilizer production equipment, businesses can build sustainable systems that benefit both agriculture and the environment.

LANE Heavy Industry continues to support this global shift with reliable, efficient, and eco-friendly equipment solutions — helping the world grow greener, one cup of coffee at a time.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520